A high-tech enterprise specializing in the research and development,production and sales of laminated glass equipment and laminated films,its products include EVA laminated glass machines,autoclave for glass laminating,composite material autoclave,intelligent PVB glass laminating lines and EVA,TPU films.

Learn MoreThe main products include EVA lamianted glass machines,autoclave,intelligent PVB glass laminating lines and EVA,TPU films.

- Laminated glass machine

- Autoclave

- Glass laminating line

- Autoclave for glass laminating

- Glass film

- TPU film

- Glass washing machine

- Glass heat soak furnace

- Glass tempering machine

-

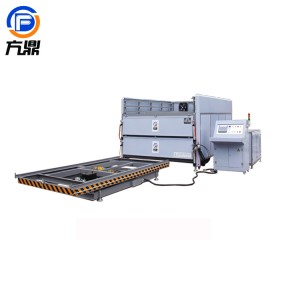

FOUR LAYER LAMINATED GLASS MACHINE Laminated glass machineCheck Our Products

The machine have 2 operation systems,can laminate different kinds of glass with different parameters at the same time,realize cycle work,reduce costs and increase efficiency.

The independent vacuum system has the functions of power failure and pressure maintenance,oil-water separation,pressure relief alarm,maintenance reminder,dust prevention and noise reduction,etc.

Multi-layer independent heating and modular area heating control,make the machine has fast heating speed,high efficiency and small temperature difference.

The insulation layer is seamlessly processed to reduce heat loss,the insulation effect is stronger,and it is more energy-saving.

The machine adopts PLC control system and the new humanized UI interface,the whole process of machine status can be visualized,and all procedures can be completed automatically.

New upgraded design,the lifting platform has a one-button lifting function,and the full-load glass lifts without deformation and rebound.

-

DOUBLE LAYER LAMINATED GLASS MACHINE Laminated glass machineCheck Our Products

Adopt the unqiue design structure of double track,which can be used flexibly by single or double stations.

Super large curved architecture laminated glass can be formed at one time.

The machine is heating fast and evenly,energy saving 40%~50%.

The machine has the function of reservation startup,timed shutdown,automatic door opening and cloud control.

-

How is laminated glass manufactured? Laminated glass machineCheck Our Products

The EVA laminating furnace is easy to operate and completes the operation in one step. Lamination-into the furnace-cooling-finished product

-

EVA glass film laminator for exterior use Laminated glass machineCheck Our Products

Model: D-J-2-2

Machine Type: Glass Laminating MachineMax. Glass size: 2000*3000mm*2-layer

Production Capacity: 36 sqm/cycle

Place of Origin : Shandong, China

Voltage: 220/380/440V, can be customized

Power: 33KW

Dimension(L*W*H): 2600*4000*1150mm

Weight: 2200kg

-

Dependable Autoclaves for Premium Composites AutoclaveCheck Our Products

The working principle of a autoclave can is to seal carbon fiber composite structural components in a vacuum bag on a mold, place them in the hot press can, and in a vacuum state, go through a process of heating, pressurization, insulation, pressure holding, cooling, and pressure relief to obtain high-performance composite products.

-

Advanced Autoclave Capabilities:Enhances Composite Material Manufacturing AutoclaveCheck Our Products

The working principle of a autoclave can is to seal carbon fiber composite structural components in a vacuum bag on a mold, place them in the hot press can, and in a vacuum state, go through a process of heating, pressurization, insulation, pressure holding, cooling, and pressure relief to obtain high-performance composite products.

-

Precision Composite Autoclaves AutoclaveCheck Our Products

The working principle of a autoclave can is to seal carbon fiber composite structural components in a vacuum bag on a mold, place them in the hot press can, and in a vacuum state, go through a process of heating, pressurization, insulation, pressure holding, cooling, and pressure relief to obtain high-performance composite products.

-

Easy to Operate Fully Automatic Laminated Glass Production Line Glass laminating lineTechnical features 1.All parts of the whole line adopt PLC centralized control system,frequency conversion,3 sets of HMI interface operation. 2.The special purpose part is equipped with encoder and servo motor to ensure stability and processing accuracy during production.The whole machine runs smoothly and reliably. 3.The whole production line is designed with high efficiency,energy saving,environmental protection,lower noise and other features. 4.Each part of the whole line can realize comm...Check Our Products

-

High-Quality Intelligent Laminated Glass Production Line Glass laminating lineTechnical features 1.The washing machine has a solid structure,beautiful appearance,energy-saving design,equipped with shutdown protection function,and an independent wind-supply system to make the glass more cleaner. 2.Glass positioning conveyor with fast positioning speed and high precision performance,suitable for the large pieces of glass production. 3.Double-station glass combining machine composed of front and rear stations,which is convenient for glass combination and film cutting,and...Check Our Products

-

Efficient and Energy-saving Fully Automatic Laminated Glass Production Line Glass laminating lineTechnical features 1.All parts of the whole line adopt PLC centralized control system,frequency conversion,3 sets of HMI interface operation. 2.The special purpose part is equipped with encoder and servo motor to ensure stability and processing accuracy during production.The whole machine runs smoothly and reliably. 3.The whole production line is designed with high efficiency,energy saving,environmental protection,lower noise and other features. 4.Each part of the whole line can realize comm...Check Our Products

-

Intelligent Laminated Glass Production Line Glass laminating lineTechnical features 1.The washing machine has a solid structure,beautiful appearance,energy-saving design,equipped with shutdown protection function,and an independent wind-supply system to make the glass more cleaner. 2.Glass positioning conveyor with fast positioning speed and high precision performance,suitable for the large pieces of glass production. 3.Double-station glass combining machine composed of front and rear stations,which is convenient for glass combination and film cutting,and...Check Our Products

-

Precision SGP Glass Autoclave for Flat and Curved Laminated Glass Autoclave for glass laminatingCheck Our Products

It is designed and manufactured in strict accordance with the national standards,It is composed of the body , the heating system, the air circulation system, the heat preservation system, the cooling system and the safety interlock system .The gate is equipped with mechanical and electrical linkage device,it will alarm under over-temperature or over-pressure,and will cool down under over-temperature and relief pressure under over-pressure .

-

Laminated Glass Autoclave — Automotive/Architectural/Ballistic Applications Autoclave for glass laminatingCheck Our Products

It is designed and manufactured in strict accordance with the national standards,It is composed of the body , the heating system, the air circulation system, the heat preservation system, the cooling system and the safety interlock system .The gate is equipped with mechanical and electrical linkage device,it will alarm under over-temperature or over-pressure,and will cool down under over-temperature and relief pressure under over-pressure .

-

Precision SGP Glass Autoclave for Flat and Curved Laminated Glass Autoclave for glass laminatingCheck Our Products

It is designed and manufactured in strict accordance with the national standards,It is composed of the body , the heating system, the air circulation system, the heat preservation system, the cooling system and the safety interlock system .The gate is equipped with mechanical and electrical linkage device,it will alarm under over-temperature or over-pressure,and will cool down under over-temperature and relief pressure under over-pressure .

-

Laminated Glass Autoclave with Safety Interlock Autoclave for glass laminatingCheck Our Products

It is designed and manufactured in strict accordance with the national standards,It is composed of the body , the heating system, the air circulation system, the heat preservation system, the cooling system and the safety interlock system .The gate is equipped with mechanical and electrical linkage device,it will alarm under over-temperature or over-pressure,and will cool down under over-temperature and relief pressure under over-pressure .

-

TPUGL560 Intermediate Film For Laminating Glass Glass filmCheck Our Products

TPU intermediate film is a thermoplastic polyurethane elastomer material.Optical grade TPU is known as the pearl on the crown. It has excellent optical performance, aging resistance, good adhesion performance, and low temperature non brittleness. It is a key material essential for high-speed trains, helicopters, passenger planes, transport plane windshields, bulletproof glass armor, and ship windshields.

-

TPUGL450 Intermediate Film For Laminating Glass Glass filmCheck Our Products

TPU intermediate film is a thermoplastic polyurethane elastomer material.Optical grade TPU is known as the pearl on the crown. It has excellent optical performance, aging resistance, good adhesion performance, and low temperature non brittleness. It is a key material essential for high-speed trains, helicopters, passenger planes, transport plane windshields, bulletproof glass armor, and ship windshields.

TRANSLATE withx

EnglishTRANSLATE withEnable collaborative features and customize widget: Bing Webmaster Portal

-

TPU Intermediate Film For Laminating Glass Glass filmCheck Our Products

TPU intermediate film is a thermoplastic polyurethane elastomer material.Optical grade TPU is known as the pearl on the crown. It has excellent optical performance, aging resistance, good adhesion performance, and low temperature non brittleness. It is a key material essential for high-speed trains, helicopters, passenger planes, transport plane windshields, bulletproof glass armor, and ship windshields.

-

High clear color EVA film for laminated glass Glass filmCheck Our Products

EVA film manufacturer with 20 years experience. Super clear, high clear, color and special film are all available.

-

Multifunction glass washing and drying machine Glass washing machineCheck Our Products

It consists of an loading segment, a cleaning and drying segment, a unloading segment, an independent air supply system and a cleaning water circulation system.

-

Heat soak furnace Glass heat soak furnaceCheck Our Products

1.Uniform temperature 2.Real time monitoring 3.Good heat preservation 4.Easy system operation 6.Air duct thermal cycle

-

Forced convection glass tempering furnace Glass tempering machineCheck Our Products

Horizontal Rollers Hearth Double Chambers (Forced Convection) Flat Glass Tempering Furnace is mainly used to produce architecture glass, advanced domestic appliances, decoration glass , Automobile&Train&Ship glass, high quality thin tempered and laminated glass, lighting glass.

SSP-Series-Double-Chambers-Glass-Tempering-Furnace-2.jpg)

The main products include EVA lamianted glass machines,autoclave,intelligent PVB glass laminating lines and EVA,TPU films.

Technical features 1.All parts of the whole line adopt PLC centralized control system,frequency conversion,3 sets of HMI interface operation. 2.The special purpose part is equipped with encoder and servo motor to ensure stability and processing accuracy during production.The whole machine runs smoothly and reliably. 3.The whole production line is designed with high efficiency,energy saving,environmental protection,lower noise and other features. 4.Each part of the whole line can realize comm...

Technical features 1.The washing machine has a solid structure,beautiful appearance,energy-saving design,equipped with shutdown protection function,and an independent wind-supply system to make the glass more cleaner. 2.Glass positioning conveyor with fast positioning speed and high precision performance,suitable for the large pieces of glass production. 3.Double-station glass combining machine composed of front and rear stations,which is convenient for glass combination and film cutting,and...

Technical features 1.All parts of the whole line adopt PLC centralized control system,frequency conversion,3 sets of HMI interface operation. 2.The special purpose part is equipped with encoder and servo motor to ensure stability and processing accuracy during production.The whole machine runs smoothly and reliably. 3.The whole production line is designed with high efficiency,energy saving,environmental protection,lower noise and other features. 4.Each part of the whole line can realize comm...

Product Advantages 1. Temperature control The temperature control of the device adopts multi overlapping and self-learning temperature control technology to achieve stepless adjustment of heating and cooling rates, avoiding curve”collapse” during high-temperature cooling. 2. Pressure control The pressure control of the equipment adopts acceleration imitation Archimedes wire control technology to achieve stepless adjustment of the rate of pressure rise and fall. 3. Design of cir...

FANGDING TECHNOLOGYCO.,LTD Laminated glass autoclave THE PREFERRED EQUIPMENT FOR AUTOCLAVE FOR GLASS LAMINATING Laminated glass autoclave –TO PROVIFE YOU WITH HIGH-QUALITY PRODUCTS– Product Features Technical Parameters Customization can be made according to the actual needs of customers Name Units DN2100*6000 DN2600*6000 DN2860*6000 DN3000*6000 DN3200*8000 DN3600*8000 DN3800*8000 Inner diameter mm 2100 2600 2860 3000 3200 3600 3800 G...

FANGDING TECHNOLOGYCO.,LTD Laminated glass autoclave THE PREFERRED EQUIPMENT FOR AUTOCLAVE FOR GLASS LAMINATING Laminated glass autoclave –TO PROVIFE YOU WITH HIGH-QUALITY PRODUCTS– Product Features Technical Parameters Customization can be made according to the actual needs of customers Name Units DN2100*6000 DN2600*6000 DN2860*6000 DN3000*6000 DN3200*8000 DN3600*8000 DN3800*8000 Inner diameter mm 2100 2600 2860 3000 3200 3600 3800 G...

FANGDING TECHNOLOGYCO.,LTD Laminated glass autoclave THE PREFERRED EQUIPMENT FOR AUTOCLAVE FOR GLASS LAMINATING Laminated glass autoclave –TO PROVIFE YOU WITH HIGH-QUALITY PRODUCTS– Product Features Technical Parameters Customization can be made according to the actual needs of customers Name Units DN2100*6000 DN2600*6000 DN2860*6000 DN3000*6000 DN3200*8000 DN3600*8000 DN3800*8000 Inner diameter mm 2100 2600 2860 3000 3200 3600 3800 G...

Product Advantages 1. Temperature control The temperature control of the device adopts multi overlapping and self-learning temperature control technology to achieve stepless adjustment of heating and cooling rates, avoiding curve”collapse” during high-temperature cooling. 2. Pressure control The pressure control of the equipment adopts acceleration imitation Archimedes wire control technology to achieve stepless adjustment of the rate of pressure rise and fall. 3. Design of cir...

Fangding Technology Co.,Ltd. FOUR-LAYER,DOUBLE CIRCULATION EVALAMINATED GLASS MACHINE Newly Upgraded Safe and Reassuring Product Introduction Model NO. FD-J-4-4 Rade Power 52kw Outside Dimension(mm) 2730*4600*2150 Voltage Customizable Layer 4 Maximum Glass Thickness 40mm Vacuum Bag 100% Improted Materials Trademark FANGDING Specification 2440*3660*4layers HS Code 84752919 Processing Glass Size(mm) 2200*3660*4layers Floor Space(mm...

Fangding Technology Co.,Ltd. FOUR-LAYER,DOUBLE CIRCULATION EVALAMINATED GLASS MACHINE Newly Upgraded Safe and Reassuring Product Introduction Model Processing glass size (mm) Rated power Operation system N.W. Outside dimonsion (mm) Floor space (mm) Production capacity (m2/cycle) FD-J-2-4 2000*3000*4 layers 38kw Siemens PLC 3700kgs 2530*4000*2150 3720*9000 72 FD-J-3-4 2200*3200*4 layers 45kw Siemens PLC 3900kgs 2730*4200*2150 4020*9500 84 FD-J-4-4 ...

Product Advantages 1. Temperature control The temperature control of the device adopts multi overlapping and self-learning temperature control technology to achieve stepless adjustment of heating and cooling rates, avoiding curve”collapse” during high-temperature cooling. 2. Pressure control The pressure control of the equipment adopts acceleration imitation Archimedes wire control technology to achieve stepless adjustment of the rate of pressure rise and fall. 3. Design of circular air duc...

Fangding Technology Co.,Ltd. FOUR-LAYER,DOUBLE CIRCULATION EVALAMINATED GLASS MACHINE Newly Upgraded Safe and Reassuring Product Introduction Model Processing glass size (mm) Rated power Operation system N.W. Outside dimonsion (mm) Floor space (mm) Production capacity (m2/cycle) FD-J-2-2 2000*3000*2 layers 26kw Siemens PLC 2200kgs 2600*4000*1150 3700*9000 36 FD-J-3-2 2200*3200*2 layers 28kw Siemens PLC 2400kgs 2750*4200*1150 4000*9500 42 FD-J-4-2 2200*3660...

Fangding Technology Co., Ltd. is a high-tech enterprise which was founded in October 2003, located in Taoluo industrial park, Donggang district, Rizhao city, covering an area of more than 20,000 square meters, with a registered capital of 100 million yuan, specializing in developing, manufacturing and selling the laminated glass equipment and the interlayer films, the main products are EVA laminated glass machine,autoclave,intelligent PVB glass laminating line and EVA,TPU films.

view more

-

0 +

Years Industry Experience

-

0 + ㎡

Factory Area

-

0 +

Countries and regions

-

0 +

Honorary title

A high-tech enterprise specializing in the research and development, production and sales of laminated glass equipment and laminated films

-

Global certifications

Global certifications

Holding D1/D2 pressure vessel production licenses and multiple international certifications such as ISO9001/CE/CSA/TUV

01 -

Full chain products

Full chain products

D1/D2 license +ISO/CE/CSA/TUV, independent export, over 30 honors Provide a complete set of solutions for glass interlayers.

02 -

Global marketing

Global marketing

Join hands with the world's top 500 companies and conduct on-site demonstrations at international top exhibitions

03 -

R&d strength

R&d strength

Experienced team + university cooperation, continuous innovation, sharing global trust

04

A benchmark enterprise in the field of assembly line equipment and intelligent assembly lines in China

-

Building curtain walls and safety glass copy

Building curtain walls and safety glass copySmart refrigerator partition, touch panel, LED conductive glass

View more >> -

Automobiles and Transportation

Automobiles and TransportationSmart refrigerator partition, touch panel, LED conductive glass

View more >> -

Photovoltaic new energy

Photovoltaic new energySmart refrigerator partition, touch panel, LED conductive glass

View more >> -

-

Aerospace and shipbuilding

Aerospace and shipbuildingSmart refrigerator partition, touch panel, LED conductive glass

View more >>

Our products are exported to over 60 countries and we have collaborated with many Fortune 500 companies. We have continuously showcased our products at top glass exhibitions such as Dusseldorf in Germany, Milan in Italy, and Atlanta in the United States. On-site processing demonstrations demonstrate our technical strength.

Fangding

It holds the D1/D2 pressure vessel production license and multiple international certifications such as ISO9001/CE/CSA/TUV, has independent export rights, and has received over 30 honors including provincial high-tech enterprise and gazelle enterprise.

The main products include EVA lamianted glass machines,autoclave,intelligent PVB glass laminating lines and EVA,TPU films.