Dry laminated glass is to laminate a layer of EVA film between two pieces of glass by a machine. Even if the glass breaks, the fragments will be stuck to the film, and the surface of the broken glass will remain clean and smooth. This effectively prevents fragment injuries and penetrating falls, ensuring personal safety. Strong penetration resistance.

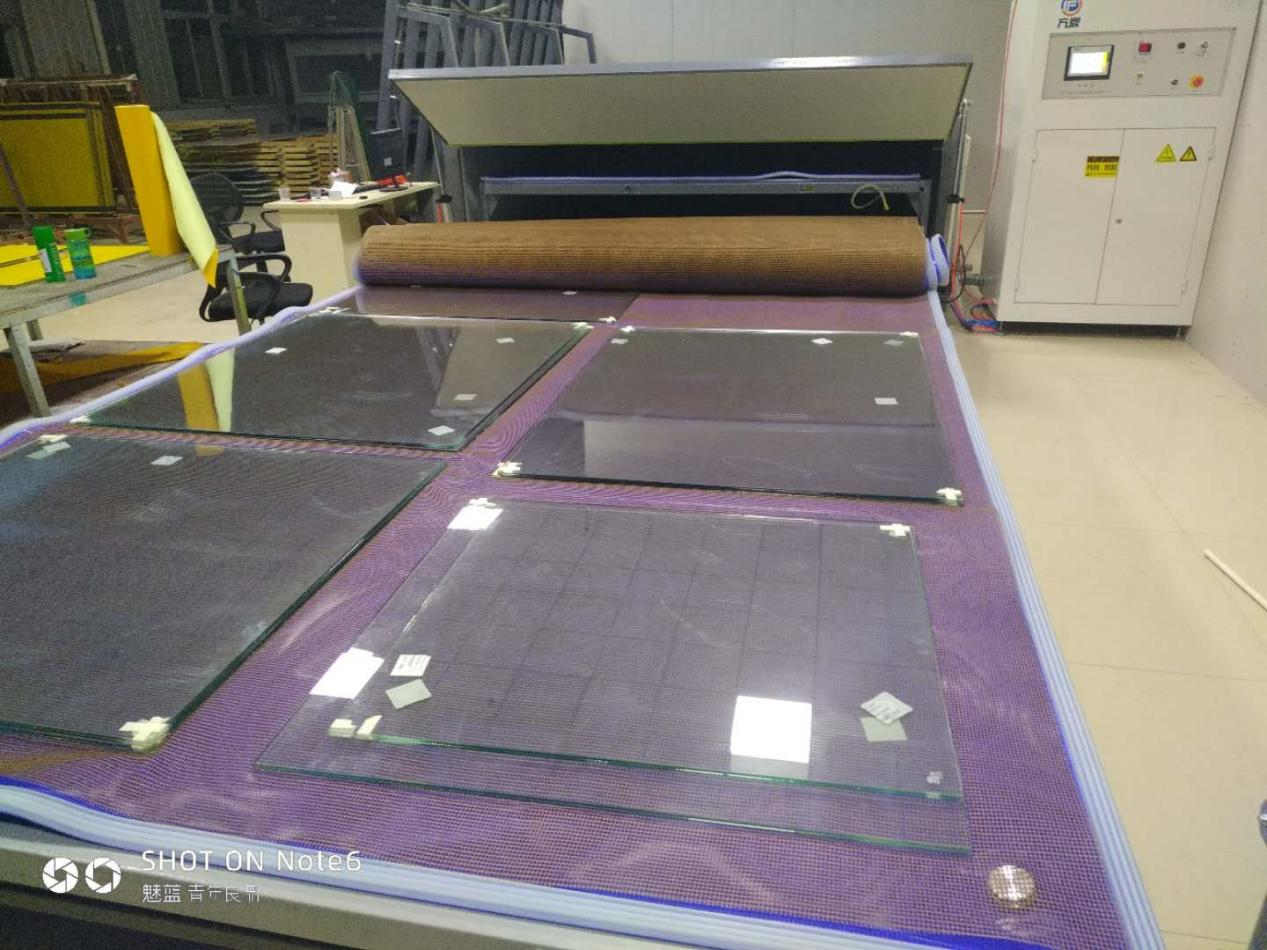

Dry lamination is a product synthesized from EVA film under high temperature and vacuum. Wet lamination is formed by solidifying the glue under the irradiation of ultraviolet rays.

Wet laminated glass is to pour synthetic resin between two pieces of glass, and then bake it with sunlight or ultraviolet light to make the two pieces of glass stand together. It can also achieve the effect of not falling off after being broken, but the strength is not as good as that of anti-resistant laminated glass made by the machine. The aging effect is not as good as that of EVA.

EVA laminated glass is made by laminating the EVA interlayer film between glass and processing it under high temperature and vacuuming. Laminated glass made of transparent EVA film has basically the same appearance and installation method as ordinary glass, and is durable.

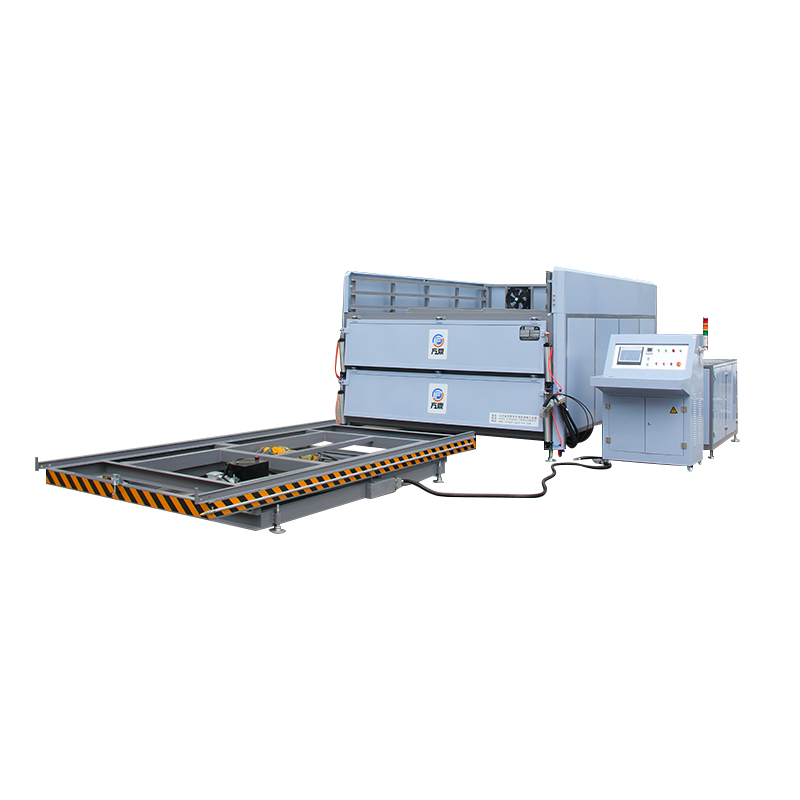

Nowadays, customers generally use one-step laminated furnace, which can produce small batches. It has low investment, small area and cheap electricity bills. The laminated glass chosen is a true safety glass and is widely used in building doors, windows, curtain walls, lighting ceilings and skylights. , indoor glass partitions and other places.

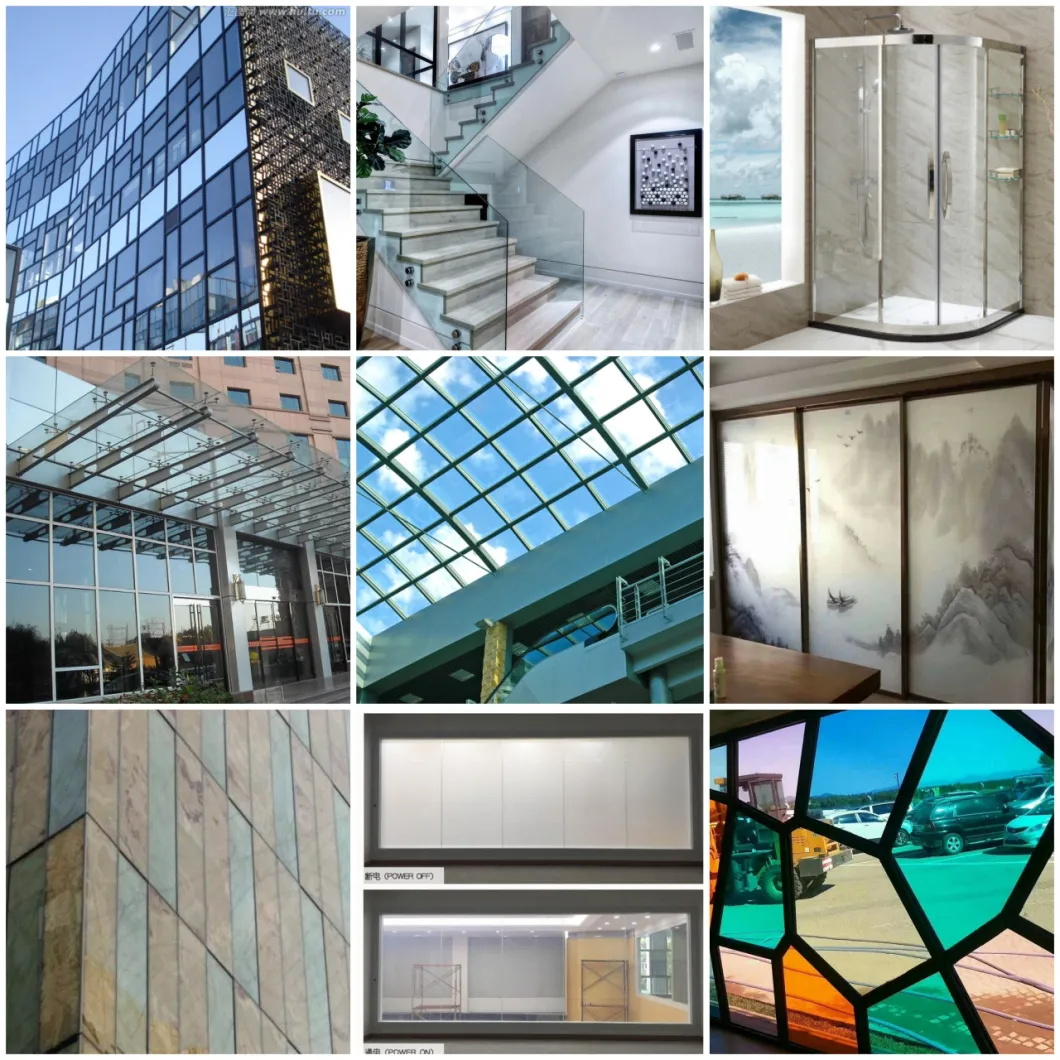

The EVA film used in laminated glass has very good toughness. When the laminated glass is violently impacted by an external force, the laminated film will absorb a large amount of impact energy and rapidly attenuate it, so the laminated glass is difficult to break. Even if the glass is broken, it can still remain intact within the door and window frame. Laminated glass is widely used in building doors and windows, curtain walls, lighting ceilings, skylights, suspended ceilings, elevated floors, large-area glass walls, indoor glass partitions, glass furniture, shop windows, counters, aquariums and almost all occasions where glass is used.

Categories: Ordinary transparent and colored laminated glass, coated laminated glass, tempered laminated glass, LOW-E laminated glass, etc.

Laminated glass is two layers of glass, with air extracted from the middle to create a vacuum state, which plays the role of thermal insulation and sound insulation. Compared with ordinary glass, tempered glass, and wet frosted glass, silk, and paper glass have the following advantages: 1. It does not fall off after being broken, and is safer than tempered glass; 2. Beautiful: the silk and paper in the middle are highly selective, and can be used to clip calligraphy and paintings; 3. Can be used for background walls, partitions, ceilings, suspended views, screens, sliding doors, countertops, etc.; 4. Compared with wet lamination, it does not produce mold or bubbles. It is an indispensable material for modern home fashion and avant-garde decoration.

Fangding Technology has focused on the research, development and production of laminated glass equipment for more than 20 years. The equipment has been widely used in countries around the world and is well received by customers. If you want to know more about our machines, please feel free to contact us!

Post time: Feb-01-2024