1) The huge disparities on price

We only need to spend about 20–40 thousands US$ on a laminated production line according to the size of the equipment. It couldn’t be better for us if it is coupled with glass edge polisher and glass washing machines, Then we can produce high quality laminated glass with relatively little investment. And which will repay you very quick.

It costs 140-350 thousands US$ on a production line of the autoclave to produce the PVB laminated glass, as the production line should be coupled with thermostatic chamber, roller presses, washing machine, edge polishers, glass cutting machine, and secondary generator. We are highly risked if we invest so much money on the autoclave production line while it pays back much more slowly.

2) The different processing procedures.

The operating process of autoclave production line is complex, and technical requirements are relatively high. First, it is really demanding for us to cut desired glass

within 2mm measurement errors, otherwise bubble will turn up in the process. And then we have to go through all the following procedures, polishing the edge, washing the glass, putting two glasses together with film in between, heating and rolling twice, edge sealing, molding into shape in the autoclave by heating and pressing, and lastly cooling. Only in this way we can produce the laminated glass. But it costs about 6 hours to finish the whole process and highly technical demanding on the control of time and temperature. Once we make a mistake in some a process, all the effort comes into vain because all the glass are useless. Gradually the burgeoning laminated production line is taking its place.

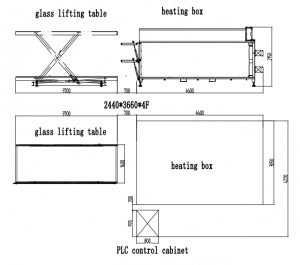

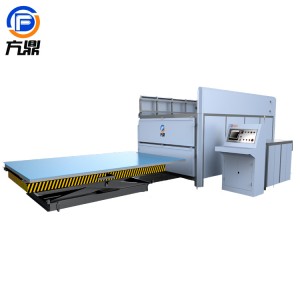

The process of Fangding laminated glass production line is quite simple and easy to control with producing technology easy to master. We can get the ideal laminate glass by vacuuming and heating glass in the equipment after cutting, polishing, washing, bonding. The whole process is PLC operated so that we can enhance efficiency and get desired glass.

3) Different working power for the equipment.

PVB laminated production line is powered by 500KW, so the consumption on the electricity is huge and generally requires a transformer to go along with. EVA laminated production line is simplified with low consumption on electricity. It is powered by 30kw- 75kw according to different size of the equipment.

4) Different production cycle and production

It takes us 6 hours to finish producing glass with a PVB laminated production line. What’s worse, we must adjust the period to even longer according to the number and thickness of glass. As a result, we can only finish producing glass once a day with 400㎡-600㎡glass.

On the contrary, it takes us 1-2 hour to finish producing glass with an FANGDING laminated glass production lines. Besides, we can keep producing for 4 times a day. Take medium-sized laminated equipment for example. It is 2m long, 3m wide and 3 layered. It produces 54㎡ once a time, 4 times a day, then we can get 216㎡ glass so that the production is equal to autoclave while the cost is low. If the order is relatively small, it is really profitable with a EVA laminated production line.

5) The principles of production the laminated glass is different.

Fangding laminated glass production line adopts the principle of high temperature and vacuum with production of the laminated glass.Traditional EVA film is a kind of hot melt film, EVA film under high temperature will be melted. And which will closely stick the glass together.

At the same time The TPU film could be used in our laminated glass machine.

High pressure autoclave PVB laminated glass adopts giving the combined glass heating and high pressure to produce laminated glass. Which need to roll the combined glass first, and then put into glass autoclave , add air pressure at glass surface . The pressure on the glass need more than 13 kgs per square centimeter, The purpose is press the air bubble out which in the combined glass. And at the same time need heating the glass by high temperature . Then the PVB laminated glass could be produced.

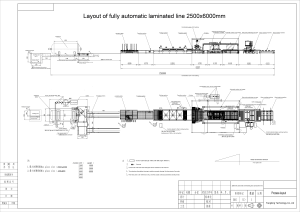

6) The equipment covers area is different.

PVB high pressure production line needs about 8M (W) *60M (L) production space, covers a big area and the production process is long.

Our laminated glass production line needs 5M (W) * 10M (L) place to produce, covers area is small, production process is simple and easy to operation.

7) The quantity of worker to operation the equipment is different.

Our laminated glass production line adopts PLC control system, usually have two worker can produce the glass. So it is save manpower and save your money.

PVB glass autoclave production line is longer than the EVA laminated glass equipment. The PVB laminated glass equipment mainly have three parts: High pressure autoclave, roller machine, constant temperature room. So the equipment need more peoples to operation.

8)The storage methods for the film are different.

The film is one of the mainly consumption material for the laminated glass. So the film is important for the security glass manufacture.

PVB films in normal temperature conditions for storage is sticky, Which have more demanding to the environment ,The film requests to be storage in a constant temperature and humidity room. Therefore enterprise need specifically built cold storage for film that increase the enterprise cost of production.

Our film(EVA), in normal temperature conditions for storage is without viscous, does not have strict request to the environment, only request storage place are clean, and not high temperature .

9) The quality of the products are difference.

1. The EVA transparency is 90% ,or so, can made glass curtain wall project, bullet-proof glass. security doors and Windows laminated glass, indoor decorative laminated glass, solar energy battery laminated glass etc.

PVB laminated glass transparency is better than EVA, transparency can reach more than 92%. PVB laminated glass can be used in the car, glass curtain wall project, bullet-proof glass, etc.

2. EVA laminated glass is more excellent PVB laminated glass in resistance against weathering and water. Because EVA laminated glass adopt the hot melt film, So that can be more fully bonded with the glass. That feature is more important to the tempered laminated glass. The EVA adhesive power is better than the PVB.

3. The intensity of the laminated glass PVB > EVA. But its only a little gap. No matter the EVA laminated glass or the PVB which can be used to the architectural glass, bullet-proof glass. door window glass and so on.

10) The equipment can manufacture the kinds of security glass are difference.

1,Our high-grade laminated glass equipment can not only produce architecture laminated glass, arc laminated glass, bullet-proof glass, patterned glass, solar battery laminated glass and art glass such as: laminated flowers/pictures/ fabric /marble glass and so on. LED laminated glass, privacy glass & switchable glass.

2,PVB laminated glass equipment generally used to produce car windshields, glass curtain wall, bulletproof glass. Because PVB laminated glass production process has many defects: Just as the temperature and high pressure that prevents to produce the art laminated glass and other type glass.

11) ,The cost for the product is different.

EVA laminated glass production cost is far below PVB laminated glass. Because EVA laminated glass both in consumption electricity, or use people, or in production process, cost is lower than the PVB laminated glass.The below information are the compare:

12) The laminated glass equipment suitable for market is different.

The Fangding laminated glass equipment, small investment, electricity consumption less, the employing less, The production quantity can be flexible adjusted by the market, according to broad market . So it can be used in most countries. Is a very good investment target!

PVB laminated glass equipment, large investment and, more electricity, large yield, employ more people. specific market scope. Usually used in a population is more, electric power resource rich cheap, national area bigger countries.

13) The equipment maintenance is different.

FANGIDNG laminated glass equipment production line is very short, production technology and equipment maintenance are easy. damageable parts replacement are simple, convenient, maintenance costs low.

PVB laminated glass equipment production line is longer, equipment maintenance parts are more, maintenance costs more. And not easy get the replacement parts from the market.

14) The equipment processing security glass safety degree is different.

Our laminated glass equipment processing technology is simple, equipment design scientific and reasonable, the noise is small, with high safety index.

PVB laminated glass equipment production cycle is longer, the whole piece of glass are made in the autoclave. when heated , the PVB film are easily to produce combustible gas in the autoclave, And the glass need be in isolation by wooden strip,Which is easily be fired by the electricity , have certain danger.

15) The equipment freight cost is different.

Our laminated glass equipment, designed scientific and reasonable for land and sea deliver, save the freight cost, generally speaking one 20 feet container can carry one set EVA laminated glass equipment and enough EVA film, Which will save a lot of money for the customer.

PVB laminated glass equipment production line is long, very weight, installation is difficulty, transportation costs is huge, Which increased much production cost.

16) Our laminated glass equipment could adopt the TPU film produce the TPU laminated glass especially in bullet-proof and windshield laminated glass. And could work with the autoclave produce the arc laminated glass. That is very import for the factory.

Post time: Jul-30-2021