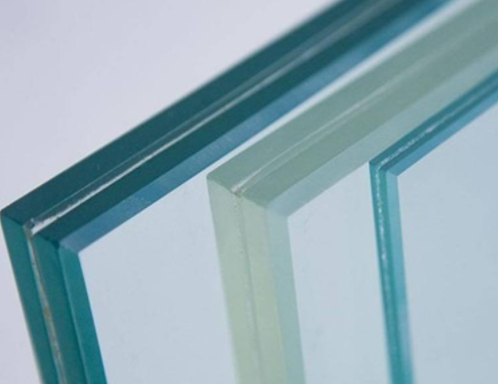

Laminated glass is made of two or more layers of flat glass (or hot bending glass) sandwiched with PVB film and made into high-grade safety glass through high pressure. It has the characteristics of transparency, high mechanical strength, UV protection, heat insulation, sound insulation, bullet proof, explosion-proof, etc. Generally, PVB interlayer is used for the interlayer of laminated glass in buildings. PVB film has the damping function of filtering sound waves (reducing the vibration amplitude of sound and volume transmission).

Two layers laminated glass machine

can be used

Fangding glue furnace production, quality assurance.

Precautions for laminated glass production process:

1. Glass processing, EVA film lamination

Cut the glass into the required size and shape, and polish the edge of the glass (which can effectively prevent the edge of the glass from cutting the silicone plate); Clean the glass (clear the dust, small particles and residual dirt on the glass, and wipe the glass with alcohol). There should be no dirt, water marks or fingerprints on the glass surface; Prepare EVA film to be cut to an appropriate size, and clip the film between the glass and the glass for lamination.

2. Preparation before entering the furnace

Put the pieces of glass on the stove frame (Note: there should be enough gap between the glasses to prevent adhesion) the suction nozzle of the silicone plate should not be blocked, otherwise the air in the silicone plate cannot be discharged completely. Out of the waste glass (it is best to use the grid for convenient exhaust), seal the silicone plate up and down, turn on the vacuum pump, and exhaust the air in the silicone plate. Before entering the furnace, be sure to check whether the vacuum bag leaks, if any, Please repair as soon as possible (if there is air leakage in the silicone plate, it cannot be heated in the furnace).

3. Glass heating

Push the glass shelf into the glue furnace, and set the required time and temperature according to the required glass.

4. Glass out of furnace

After heating and insulation, when the temperature in the box will be below 90 ℃, open the door and push out the glass frame. When the temperature drops to about 30 ℃, open the silicone plate and take out the glass.

Post time: Jul-08-2022