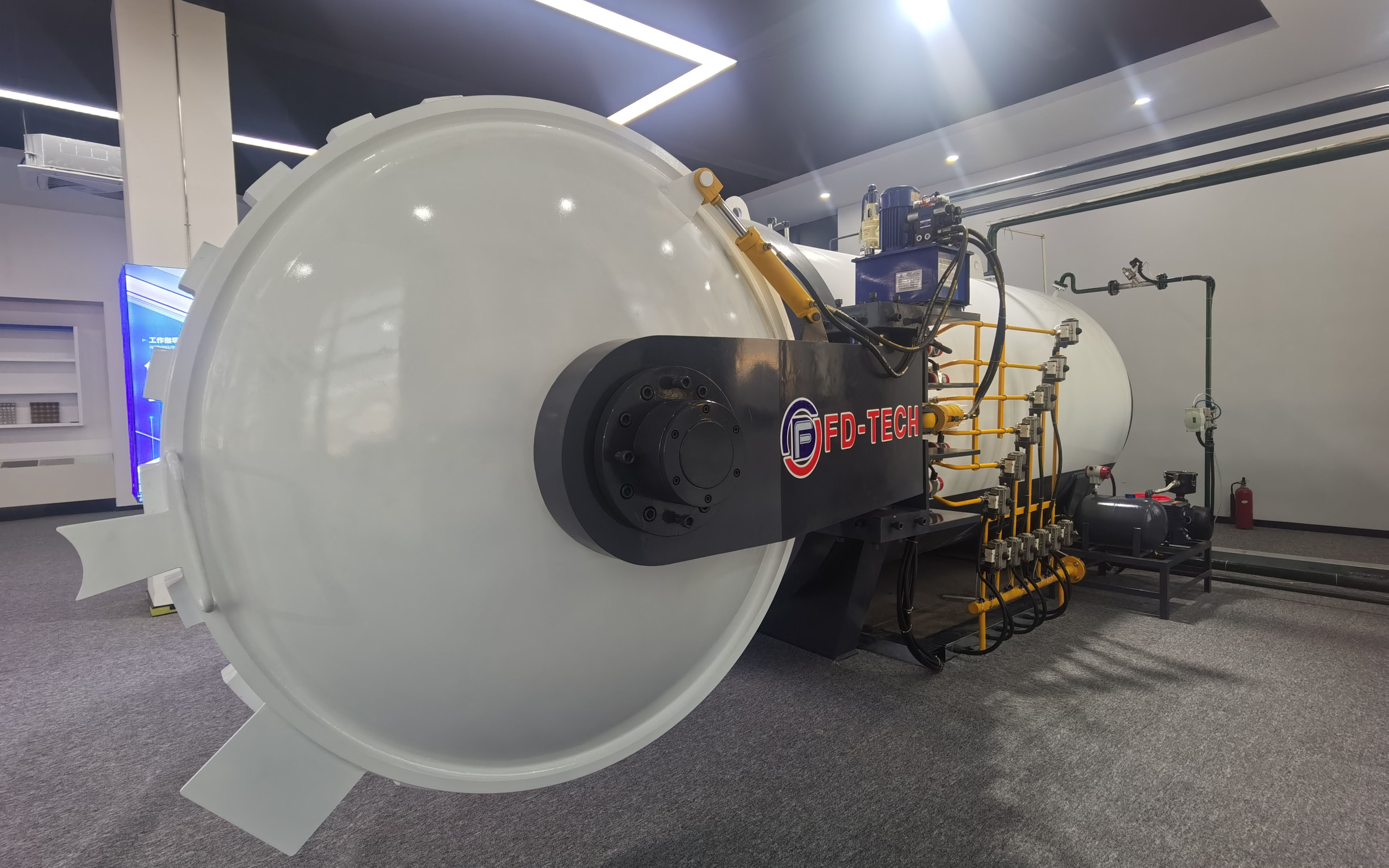

Precision Composite Autoclaves

Product Advantages

1. Temperature control

The temperature control of the device adopts multi overlapping and self-learning temperature control technology to achieve stepless adjustment of heating and cooling rates, avoiding curve”collapse” during high-temperature cooling.

2. Pressure control

The pressure control of the equipment adopts acceleration imitation Archimedes wire control technology to achieve stepless adjustment of the rate of pressure rise and fall.

3. Design of circular air duct

The equipment adopts a circular air duct design to improve temperature uniformity.

4. Fan frequency conversion control

The equipment adopts fan frequency conversion control, which adjusts the fan speed throughout the entire process according to pressure to achieve the best working state.

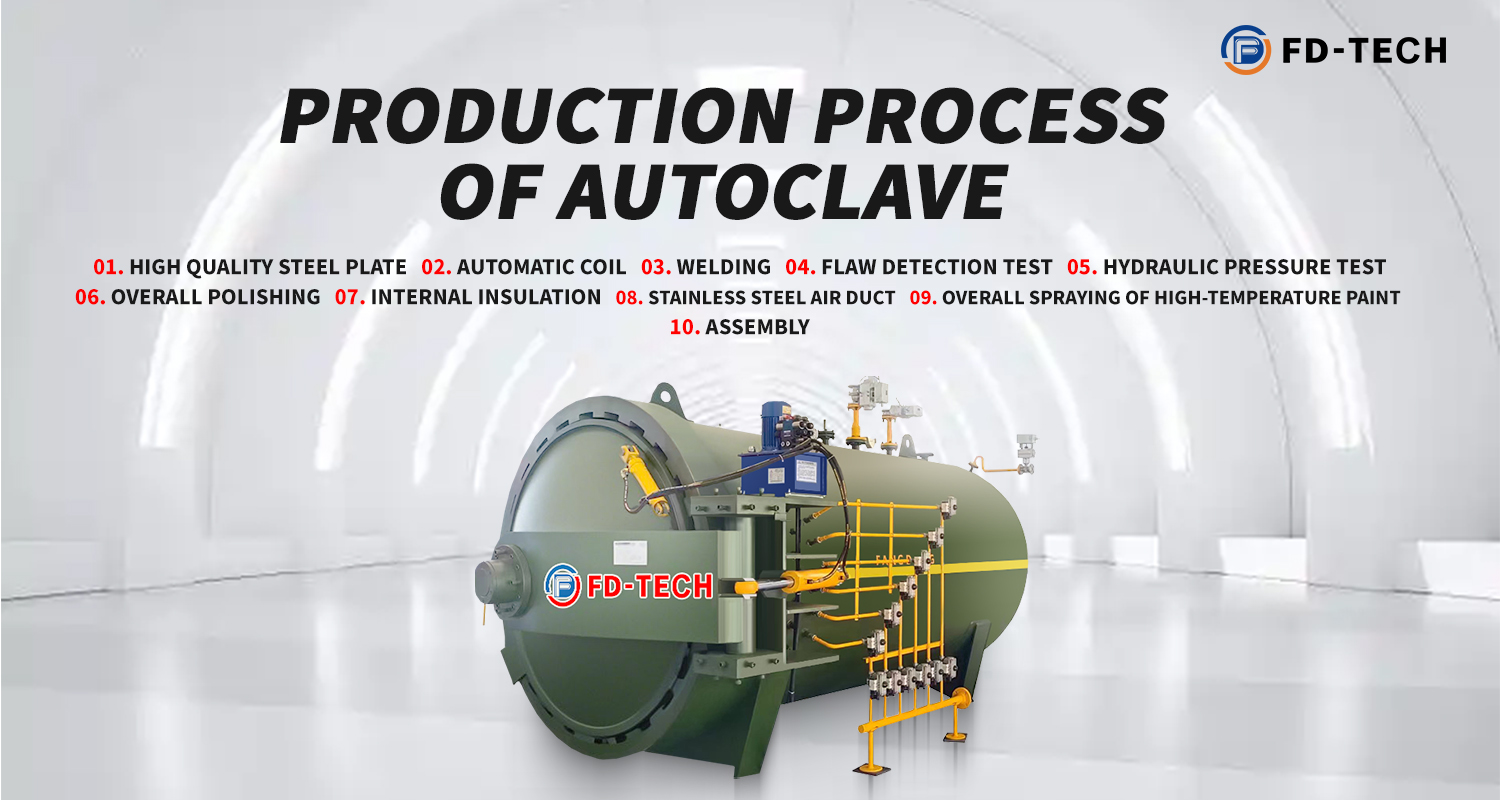

Production Process Of Autoclave

high quality steel plate → automatic coil → welding → flaw detection test → hydraulic pressure test → overall polishing → internal insulation→ stainless steel air duct → overall spraying of high-temperature paint → assembly

Equipment Application Field

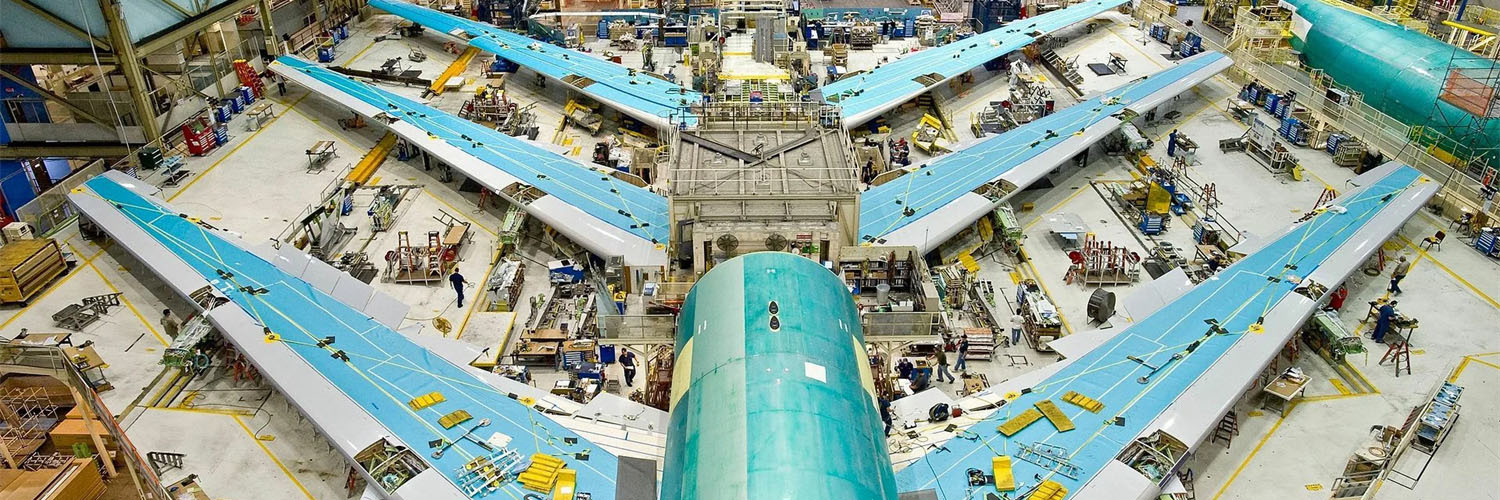

1. Aerospace field

It can manufacture aircraft wings, vertical tails, front fuselage, aerospace composite components, etc.

2. Military industry field

Bullet proof vests, helmets, armor, weapons and other composite material components.

3. Automotive industry field

Composite materials for automotive body, transmission shaft and other automotive components.

4. High speed rail track field

Composite materials for high-speed trains and subway doors and windows.

Customer Feedback

For many years, the products sold have won the trust and praise of customers both domestically and internationally with high-quality products and sincere service.

Delivery Site

During the shipping process, we will package and cover the equipment appropriately to avoid any unexpected situations and ensure that the equipment arrives at the customer's factory in good condition. Attach warning signs and provide a detailed packing list.

Service Advantages

One stop service

Integrate the full chain of resources including equipment R&D,process design,consumable supply,and operation and maintenance services to build a one-stop solution covering the customer’s production cycle.With technical integration capabilities and full process control,we help increase efficiency,control costs,and ensure worry-free operation.

After-sale service

The company is equipped with a professional technical after-sales team.From equipment selection to process implementation,from consumables adaptation to long-term operation and maintenance,we use the “four-in-one”service matrix to provide you with full life cycle managed services-making complex production support simple and letting professionals do professional things.