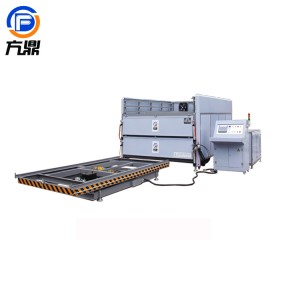

Fangding Machine Process Laminated Glass with EVA/Sgp/TPU Film

Basic Info.

| Model | FD-J--2-2 |

| Machine name | EVA glass lamination machine |

| Process Max. Glass size | 2000x3000mm |

| Specification | Double layers |

| Operation system | Siemens PLC |

| Power | 33KW |

| Net weight | 2200KGS |

| Dimension | 2600x4000x1150mm |

| Yield | 36 square meter per cycle |

| Origin | China |

| Warranty period | 1 year |

| Heating method | Forced convection |

| Application | Architecture/decorative/PDLC/LED |

Fangding Lamination Machines

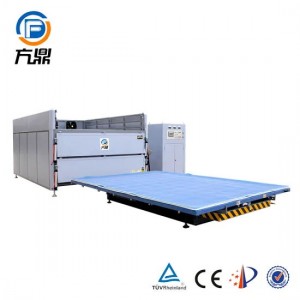

Since 2003, Fangding begin producing glass laminating machine, keep improving and inovation, using unique design of heating and vacuum systems, the heating is evenly in the heat box, temperature difference is 3-5 degrees. The glass laminating machine has two heating rooms. Make the production very smart , heating more quickly, saved around 30% engergy comparing to other Chinese machines.

EVA glass laminating machine can produce laminated glass without autoclave. Besides architecture clear laminated glass, the machine can also work with silk, paper, plastic film, metal mesh, fiber mesh, switchable film and many other materials for indoor decorative application.

Heating Elements:

The heating elements are placed in the furnace evenly and resonable. The heating is provided with electric radiant heat and is evenly distrubuted with the assisstance of convection fan for very precise heating. This setup will quickly reach the target temperature, the temperature difference is bellow 5 degrees, the heating is evenly, the laminate glass quality is excellent.

After-Sales Service:

Shipping to Canada & USA & India

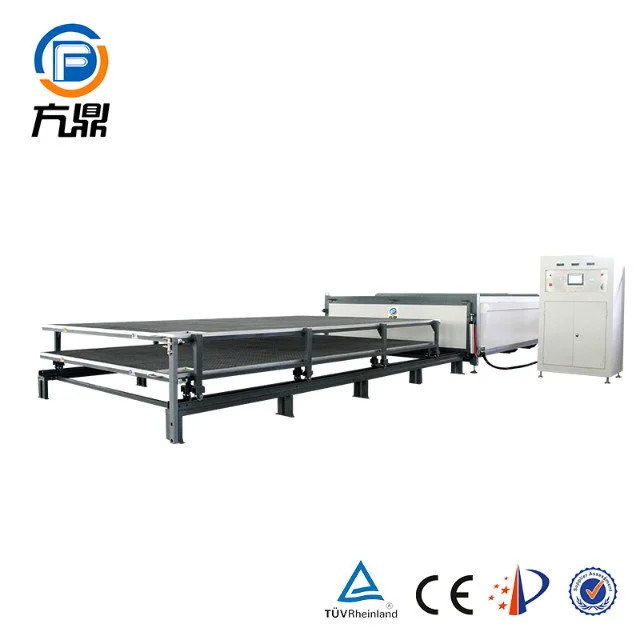

Machine main configeration

1)Siemens PLC control

2)One heating rooms

3)Two plates/layers

4)One set vacuum systems

5) One set PLC system

5)One ground rail

6)Two sets vacuum bags

7)Teflon Mesh: 2 sets

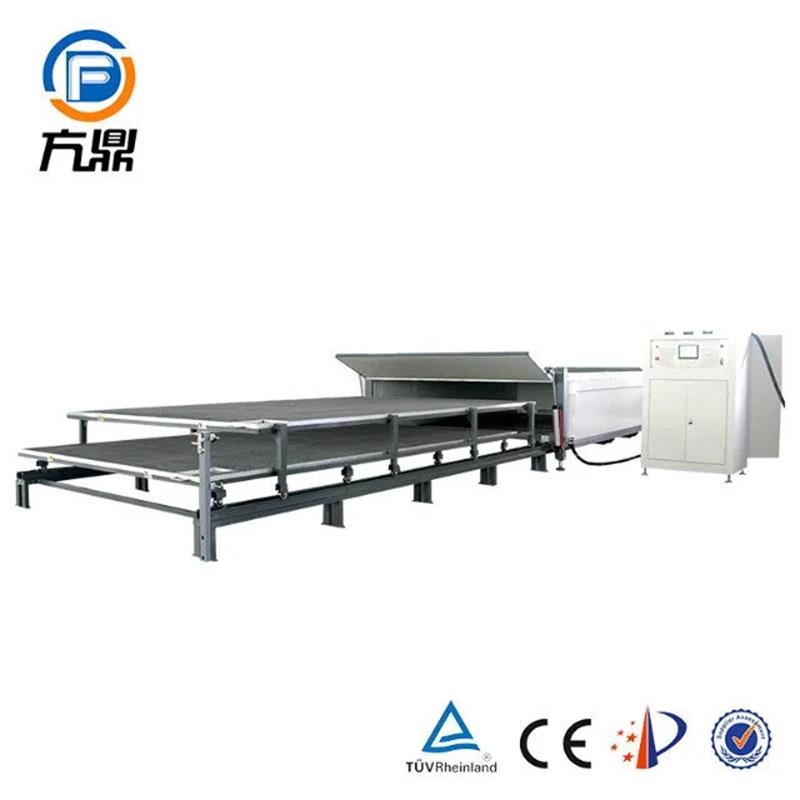

Special desgin avaliable

We are a leading manufacture in China with more than 18 years experience in glass laminated machine field. We have professional R&D and production team, if you have any special requirements, please contact with us freely. And warmly welcome you to visit us!