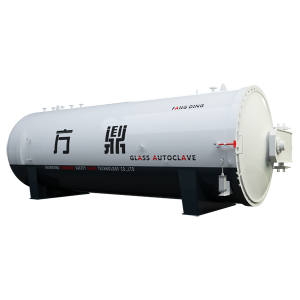

The Forced Convection Autoclave

Product Description

We provide a full range of laminated glass equipment solutions. Specifications and configurations are optional, tell us your specific requirements, and we will tailor the optimal solution for you.

| Production | Glass lamination autoclave |

| Machine model | FD-A2500 |

| Rated power | 232KW |

| Processing glass size | Max. glass size: 2500X6000mm Min.glass size: 400mmx600mm |

| Glass thickness | 4~80mm |

| Floor space | L*W: 11000mm×8000mm |

| Voltage | 220-440V 50-60Hz 3-phase AC |

| Working period | 4-6h |

| Working temperature | 60-135ºC |

| Net Weight | 20t |

| Operation system | Siemens PLC |

| Productivity | 400-600 Sq.m/cycle |

Process Flow

1. The flat laminated glass

loading one glass sheet→ transition → Cleaning and drying→ assembling → transition → preheat and prepress → unloading the combined glass sheet → into autoclave → finished product

2. The bended laminated building glass

Cleaning and drying → hot bending → cleaning and drying → assembling → vacuumize→ into autoclave → finished product

II. Company Information

1.About us

Fangding Technology Co., Ltd is a high-tech enterprise which was founded in October 2003, located in Taoluo industrial park , Donggang district, Rizhao city, covering an area of more than 20,000 square meters, with a registered capital of 100 million yuan,specializing in developing ,manufacturing and selling the laminated glass equipment and the interlayer films,the The main products are EVA laminated glass machine,Heat Soak Furnace, Smart PVB glass laminating line and EVA,TPU,SGP films.

At present, the company has D1, D2 pressure vessel production license, has obtained the ISO 9001 quality management system certification,the products have obtained the European Union CE certification, Canada CSA certification and Germany TUV certification,it has the independent export permission and successively awarded the high-tech enterprise, gazelle enterprise of Shandong province, famous brand in shandong province, and others more than 30 honorary title.

In the international market, the products has been exported to Asia, Europe, America and other more than 60 countries and regions .Be responsible for the customers and develop together with them!It has laid a solid foundation for enterprises to compete on the international stage.the company has won the trust and praise from the customers all over the world for years.

2. Workshop & Shipment

We make strict quality testing before packing by professional staff and engineer.

The machine packed with standard package, will be fixed firmly in the container.

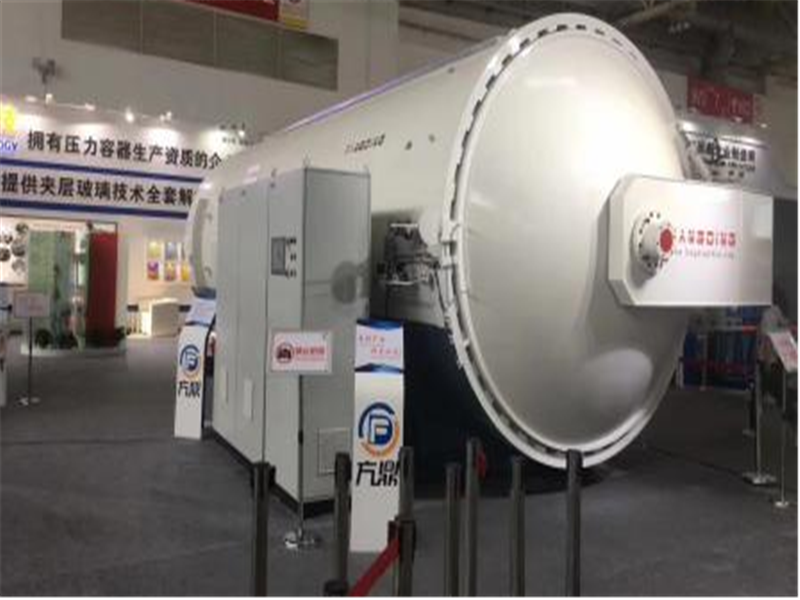

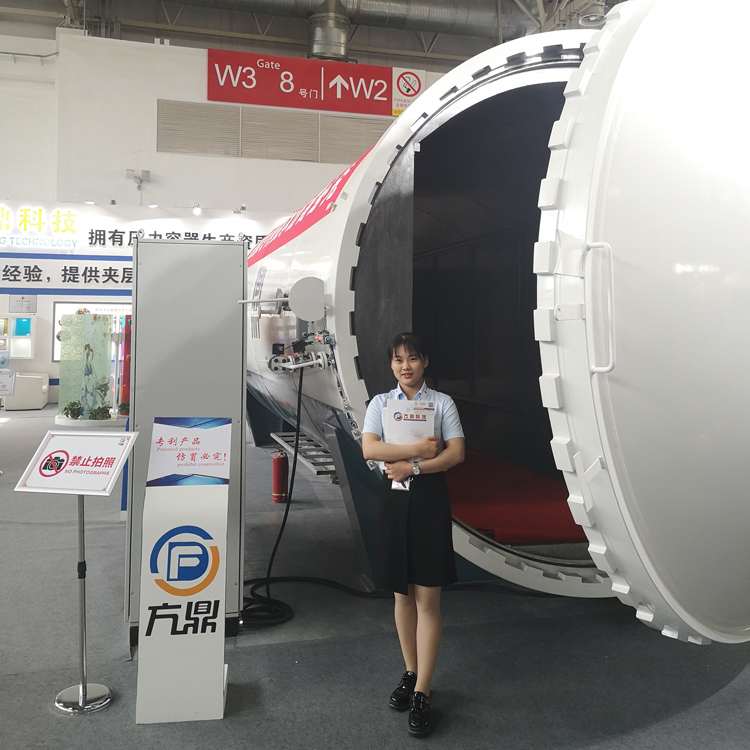

3.Exibition

We participate in large-scale industry exhibitions at home and abroad every year. Live demonstration of the machine, giving you the most intuitive experience!

4. Certificates

At present, the company has D1, D2 pressure vessel production license, has obtained the ISO 9001 quality management system certification,the products have obtained the European Union CE certification, Canada CSA certification and Germany TUV certification,it has the independent export permission and successively awarded the high-tech enterprise, gazelle enterprise of Shandong province, famous brand in shandong province, and others more than 30 honorary title.

III. Advantages

We have a professional R&D department, and our engineers have many years of practical and technical experience. From the glass loading machine, the laminating system, the pre-press machine to the autoclave, we are constantly improving and innovating, striving for excellence, and are committed to providing the market with better products.

1. Adopting new heating technology, the heating element is surrounded by four sides, strong wind convection cycle design, to achieve temperature balance in the autoclave, to ensure product quality, save energy and improve production efficiency.

2. Touch screen, PLC and other electrical appliances are equipped with international brands such as Siemens, South Korea LS, etc., with paper recording and data storage functions, real-time monitoring of temperature and pressure changes in the autoclave. Temperature and pressure with interlock control function, automatic temperature compensation, pressure compensation, to ensure pressure and temperature stability.

3. Unique cooling technology of high, middle and low grades can adjust the cooling speed according to the needs of customers or products to ensure the yield. As a main cooler, the fin heat exchanger has a large heat dissipation area and high heat exchange efficiency.

4. Device software can realize data exchange, output and storage. Call more than 40 sets of process parameters. With fault alarm and other functions.

5. Use 80mm environmentally friendly aluminum silicate insulation material, superior thermal insulation performance and reduce energy consumption.

6. All lines adopt the external wiring mode, which effectively prevents aging problems caused by excessive temperature in the furnace, prolongs the life of the line, and facilitates equipment maintenance and overhaul.

7. The company has the qualification of pressure vessel production, and the welding employs a senior technician with a certificate. Before leaving the factory, it is strictly inspected according to the pressure vessel inspection standard.

8. The company has an independent research and development department, acceptance team, from the source to the quality control of each detail, ingenuity quality.

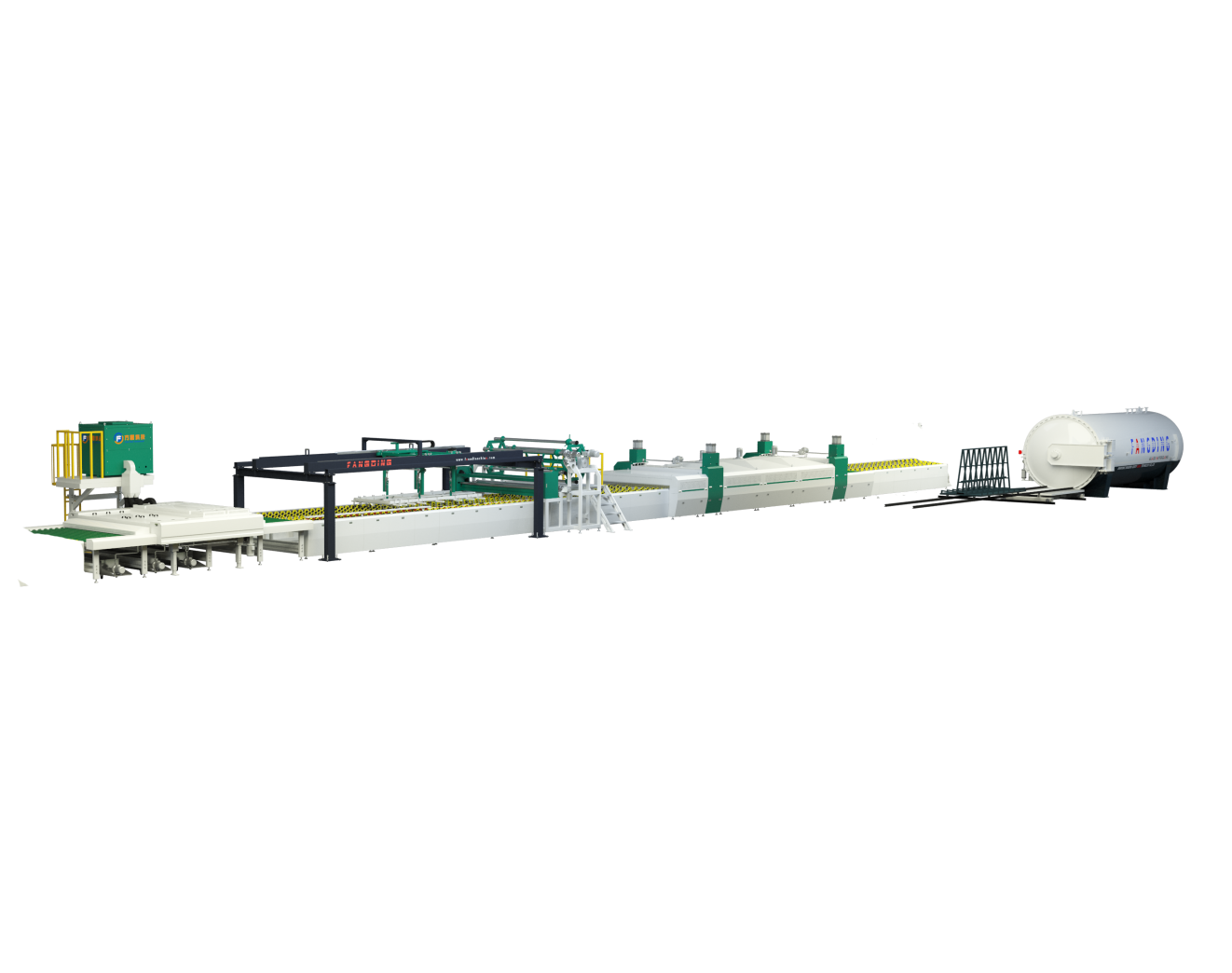

IV. Other products

In addition to the autoclave, our company also independently develops and produces laminated line. From glass loading, glass washing, glass combination, to glass rolling, we provide fully automatic production lines, and can provide you with the best quotation plan according to your detail requirements.

FAQ

Q: Are you manufacturer or trading company?

A: We are the manufacturer. The factory covers an area of more than 20,000 square meters and independently produces laminated glass production lines, especially autoclaves. We are one of the few domestic manufacturers with the qualification for producing pressure vessels.

Q: Do you accept customized sizes?

A: Yes, we do. We have a professional technology R&D and design team with more than 30 years of experience. We will design the most suitable plan for you according to your detail requirements .

Q: How long does it take to complete a processing cycle?

A: It is determined by the loading rate and product details. It usually takes 4-6 hours.

Q: How about the degree of automation of the production line?

A: We have designed fully automatic and semi-automatic production lines, customers can choose according to their budget and site.

Q: If your engineer is available to oversea to install on site?

A:Yes, our experienced engineers will come to your factory to install and commissioning the production line, and teach you production experience and operating skills.

Q: What are your payment terms?

A: 30% of the total value is paid by TT, 65% is paid before delivery, and the remaining 5% is paid during installation and commissioning.

Q: How about your after-sale service?

1. 24 hours online, solve your problems at any time.

2. The warranty is one year and the maintenance is lifelong.