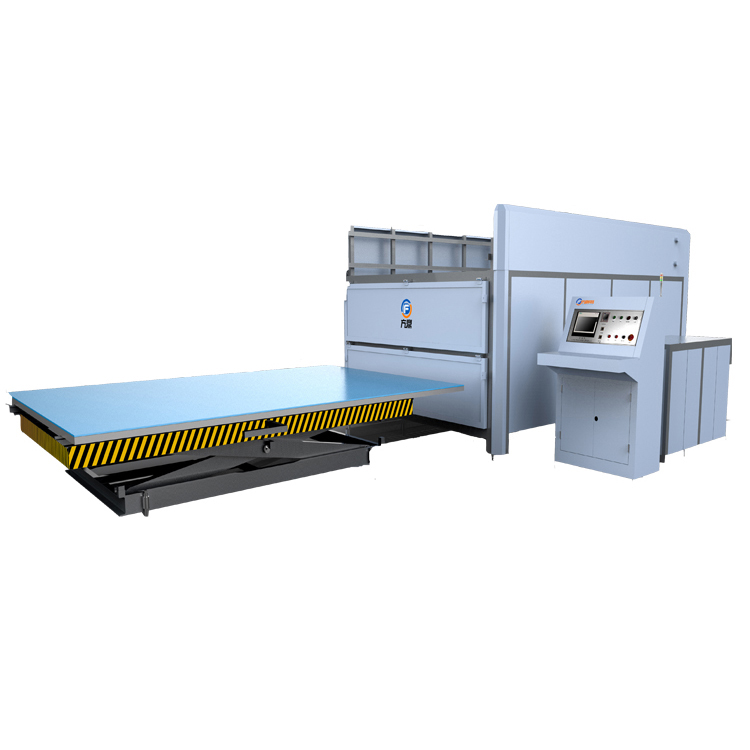

Newest Design Fangding Glass Laminate Machine (4 LAYER) on Promotion

Fangding Technology Co.,Ltd.

FOUR-LAYER,DOUBLE CIRCULATION

EVALAMINATED GLASS MACHINE

Newly Upgraded Safe and Reassuring

Product Introduction

| Model NO. | FD-J-2-4 |

FANGDING Laminating Machines

Since 2003, Fangding begin producing glass laminating machine, keep improving and inovation, we use unique design of heating and vacuum systems, the heating is evenly in the heat box, temperature difference is less than 3 degrees. The glass laminating machine has two heating rooms, each room has independent control systems.Make the producing very smart , heating more quickly, saved around 30% engergy comparing to other Chinese machines.

EVA laminating glass machine can produce laminated glass withou the use of and autoclave. The machine can work with silk, paper, plastic film, metal mesh, fiber mesh, switchable film and many other decorative film.

Heating Elements:

The heating elements are placed in the furnace evenly and resonable. The heating is provided with electric radiant heat and is evenly distrubuted with the assisstance of 2 convection fans for very precise heating. This setup will quickly reach the target temperature, the temperature difference is bellow 3 degrees, the heating is evenly , the laminate glass quality is excellent.

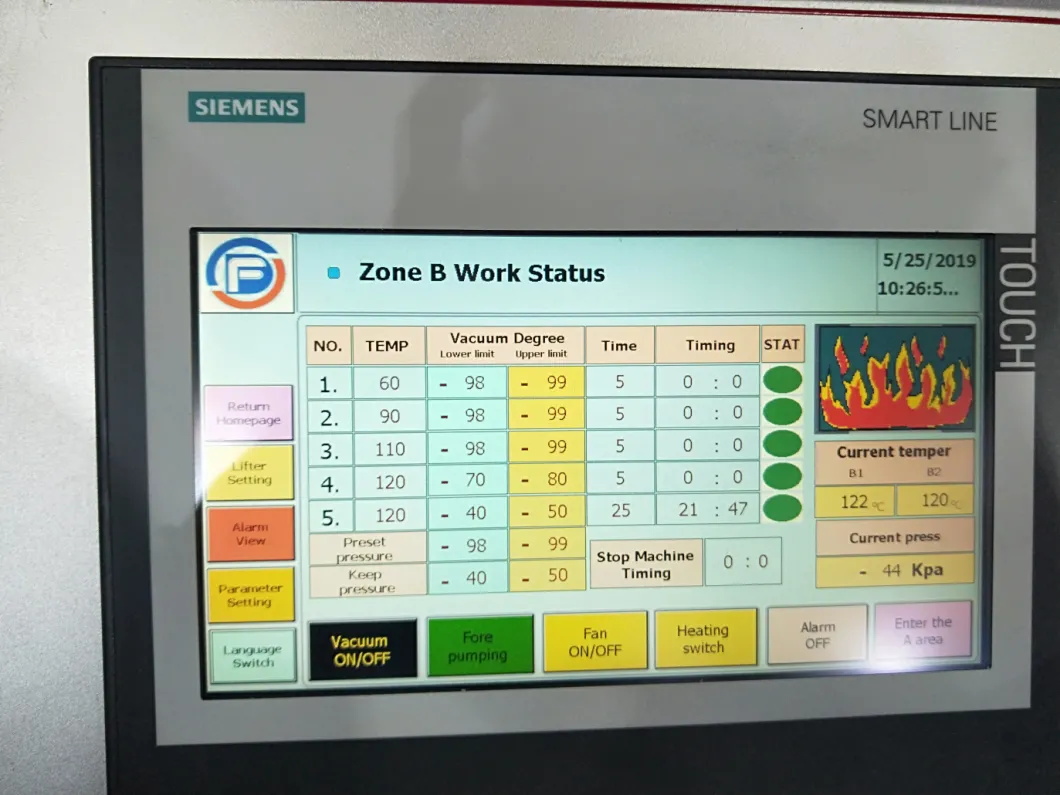

PLC control system:

Our four layers machine use two independent PLC systems.

All machines functions are controlled via PLC touch screen controls. All parameters can be easily set and adjusted for quick operation for many different types of applications. The PLC also controls the temperature which is regulated by means of adjusting voltage to the heating element, resulting in very accurate temperature control.

Scientific Design

Selling point description

FEATURES

PRODUCT NAME: Fangding EVA glass laminating machine

ITEM#: FD-J-2-4

MAIN TECHNICAL PARAMETERS:

POWER INPUT: 220-480V THREEPHASE ALTERBATING CURRENT

POWER CONSUMPTION:38KW / H

MAX PROCESSING GLASS SIZE: Max size (mm): 2000 mm*3000mm

Max Arch height (mm): 400 mm(can design as your requirement even higher)

Max Thickness (mm): 36 mm

EFFICIENCY: Forming cycle (minute/furnace): 75-90min

Max processing area (M2 /furnace): 72M2

OPERATION SYSTEM: PLC, Man machine conversation.

OPERATION PLATEFORM: 4 layers

WORKING TEMPERATURE: 90-140 0C

MACHINERY OUTSIDE DIMENTION :2530mm*4000mm*2150mm

N.W: 3700kgs

CUSTOMER CASE

The equipment is sold to Asia, Europe, Ameriaca, Southeast Asia, and has received unanimous praise from customers;

Good customer performance and the ability to mass produce orders;

Morecustomers choose to order a second unit and repeat orders for high-pressure reactors, production lines, and other products.

CUSTOMER USE CASES

The products produced by customers using equipment can be seen everywhere in daily life, such as wire clips, colored decorative glass, etc; And it has also been used in important engineering cases of world-renowned buildings and scenic spots such as glass bridges and lighthouses.

CERTIFICATE OF HONOR

R&D TECHNOLOGY TEAM

Hold a technical

review meeting

before production

Calculation based

on drawings

before production

Multiple

experienced

technical engineers

EXHIBITION STYLE

CONTACT US

Jennifer Zhu

HOT LINE +86-18906338322

Website: https://en.fangdingchina.com/

Email: sales2@foundite.com

Add: Huifeng Road, Taoluo Industrial Park, Donddang District, Rizhao City, Shandong Province, China