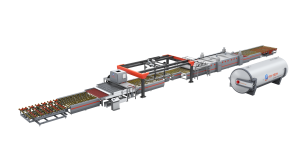

Intelligent Laminated Glass Production Line

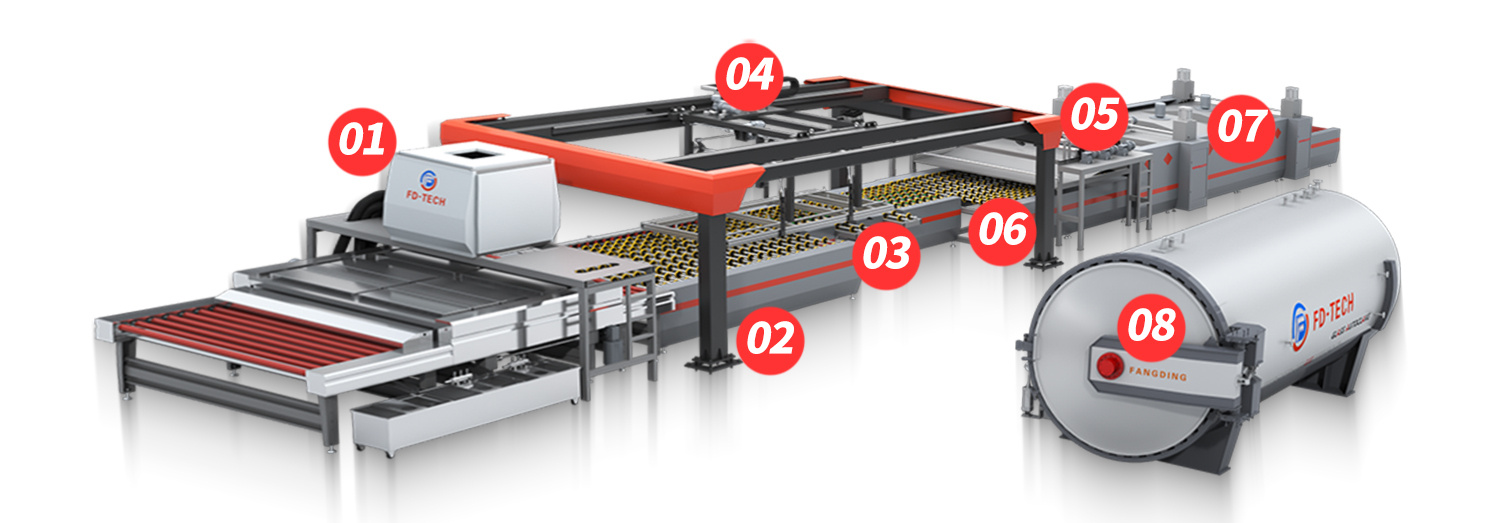

Technical features

1.The washing machine

has a solid structure,beautiful appearance,energy-saving design,equipped with shutdown protection function,and an independent wind-supply system to make the glass more cleaner.

2.Glass positioning conveyor

with fast positioning speed and high precision performance,suitable for the large pieces of glass production.

3.Double-station glass combining machine

composed of front and rear stations,which is convenient for glass combination and film cutting,and can be operated by manually and automatically.

4.Suction cup hanger machine

The suction cup of the hanger adopts special materials to ensure that no traces are left on the glass surface,so as to ensure the production of high-quality products.

5.The horizontal3-roller PVB/SGP film storage machine

The horizontal 3-roller PVB/SGP film storage machine is equipped with automatic film releasing and rolling up functions,and this design makes the film replacing work more faster and convenient.

6.The transition conveyor

The transition conveyor is designed with the best synchronous,smooth and fast production performance.

7.Pre-pressing machine

The structure of the roller pressing machine is reasonable,the operation is simple,the heating distribution is evenly,and the operation of the whole machine is stable and reliable.

Form

1.Glass washing &drying machine

2.Glass positioning conveyor or Glass taking conveyor(Alternative)

3.Double station glass combining machine

4.Semi-automatic suction cup hanger

5.The horizontal 3-roller film storage machine

6.Transition conveyor

7.Roller pressing machine

8.Glass autoclave

Optional

The laminated glass production line has selectivity,customers can choose between fully automatic laminated glass production lines and intelligent laminated glass production lines based on factors such as site and order. At the same time, our sales manager will also provide appropriate suggestions based on the actual situation and needs of customers, and customize their own laminated glass production lines to achieve better customer service.

Company strength

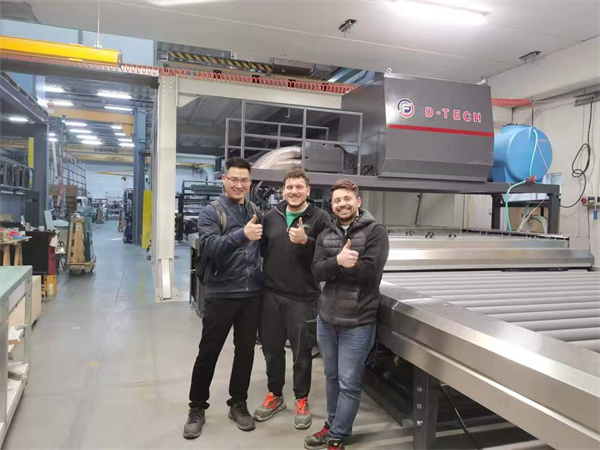

Fangding Technology Co., Ltd. was established in 2003 and is a high-tech enterprise specializing in the research and development, production, sales, and service of laminated glass equipment and laminated glass intermediate films. The company's main products include EVA laminated glass equipment, intelligent PVB laminated glass production line, autoclave, EVA, TPU intermediate film. At present, the company has a pressure vessel license, ISO quality management system certification, CE certification, Canadian CSA certification, German TUV certification and other certificates, as well as hundreds of patents, and has independent export rights for its products. The company participates in well-known exhibitions in the global glass industry every year and allows international customers to experience Fangding's design style and manufacturing process through on-site glass processing at the exhibitions. The company has a large number of skilled senior technical talents and experienced management talents, dedicated to providing a complete set of solutions for laminated glass technology for glass deep processing enterprises. Currently, it serves more than 3000 companies and multiple Fortune 500 enterprises. In the international market, its products are also exported to many countries and regions such as Asia, Europe, and the United States.

Customer feedback

For many years, the products sold have won the trust and praise of customers both domestically and internationally with high-quality products and sincere service.

Delivery site

During the shipping process, we will package and cover the equipment appropriately to avoid any unexpected situations and ensure that the equipment arrives at the customer's factory in good condition. Attach warning signs and provide a detailed packing list.

Fangding Service

Pre sales service: Fangding will provide equipment models suitable for customers based on their needs, provide technical information on relevant equipment, and provide basic design plans, general drawings, and layouts when quoting.

In sales service: After the contract is signed, Fangding will strictly implement each project and relevant standards for each production process, and communicate with customers in a timely manner about equipment progress to ensure that customer requirements are met in terms of process, quality, and technology.

After sales service: Fangding will provide experienced technical personnel to the customer's site for equipment installation and training. At the same time, during the one-year warranty period, our company will provide corresponding equipment maintenance and repair.

You can fully trust us in terms of service. Our after-sales personnel will promptly report any problems encountered to our technical personnel, who will also provide corresponding guidance.