Manufacturer for Laminated Glass Processing Kiln - EVA Laminated Glass Fabrication Equipment – Fangding

Manufacturer for Laminated Glass Processing Kiln - EVA Laminated Glass Fabrication Equipment – Fangding Detail:

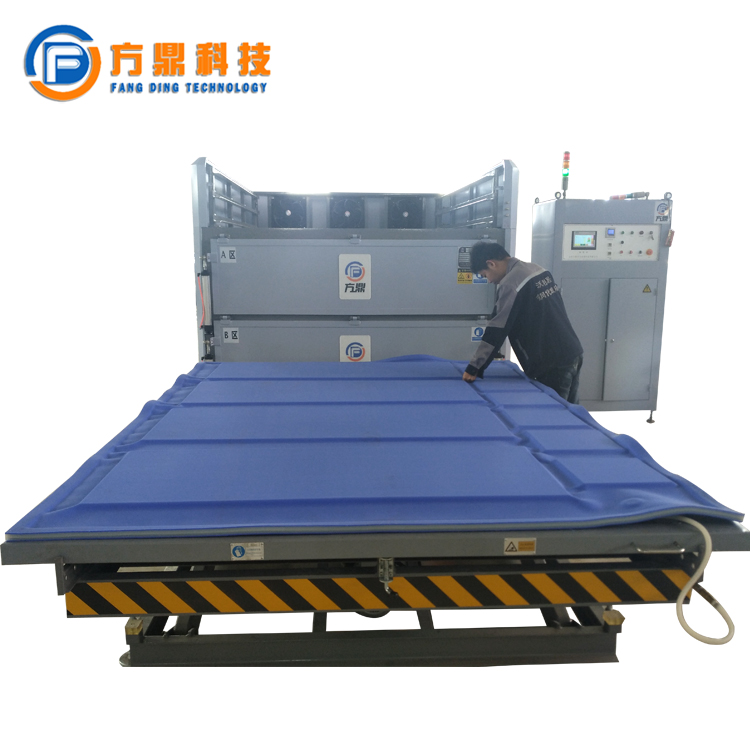

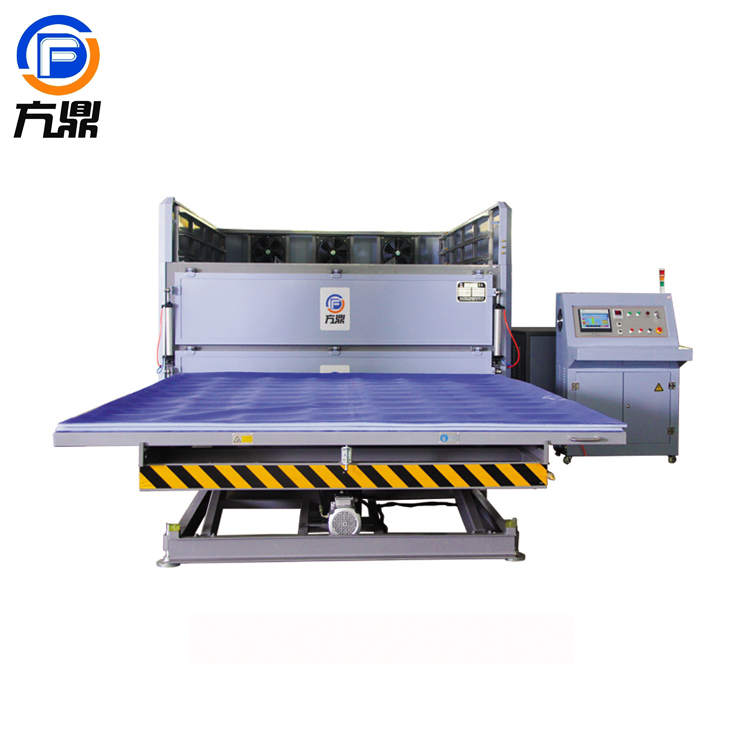

EVA Laminated Glass Fabrication Equipment

The glass laminating furnace adopts the principle of high temperature vacuum extraction.

The film is placed in the middle of two or more pieces of glass. After the high temperature vacuum in the furnace, the film and glass are tightly bonded together to achieve good transparency and no bubbles. And there is no drop after breaking.

Advantage:

* Independent heating up and down, floor heating distribution, modular control, strong convection circulation of turbine

* A number of patented technologies.The heating system uses a turbine fan and a high-density explosion-proof stainless steel electric heating rod for heating. It is equipped with a temperature sensing device, a modular area heating control, intelligent self-adjusting temperature, fast heating, uniform temperature, and strong turbo fan. Convection circulation to ensure the temperature difference in the furnace within 5 degrees.

* The insulation system adopts seamless processing to minimize heat loss. Compared with similar products and equipment, it can save energy by more than 30%.

* High-performance vacuum system with automatic vacuum pressure holding, stable working around the clock, improving product efficiency and quality.

* 99% pass rate

* 50% energy saving

* High efficiency

* PLC control, Simple to operate

* High quality spare parts

* EVA/TPU/SGP film as interlayer

* Rich range of products

* Large size bending glass processing

* No waste when suddenly power off

* Free home installation and training

Model: D-J-3-4

Model: D-J-3-4

Machine Type: Glass Laminating Machine

Max. Glass size: 2200*3200mm*4-layer

Production Capacity: 84 sqm/cycle

Place of Origin : Shandong, China

Voltage: 220/380/440V, can be customizedCe-Standard-Switchable-Glass-Laminating-Machine-with-Pdlc-Magic-Film

Power: 68KW

Dimension(L*W*H): 2730*4200*2150mm

Weight: 3900kg

Warranty: 1 Year

After-sale service: Online support, Free spare parts, Field installation, commissioning and training, Video technical support

Glass Thickness: 3-19mm

Marketing Type: New Product

Warranty of core components: 1 Year

Core Components: Motor, PLC, Pump

Product name: EVA Glass Laminating Machine

Operating temperature: 90-140℃

Control system: PLC

Heating method: Forced Convection

Operation: Automatic Control

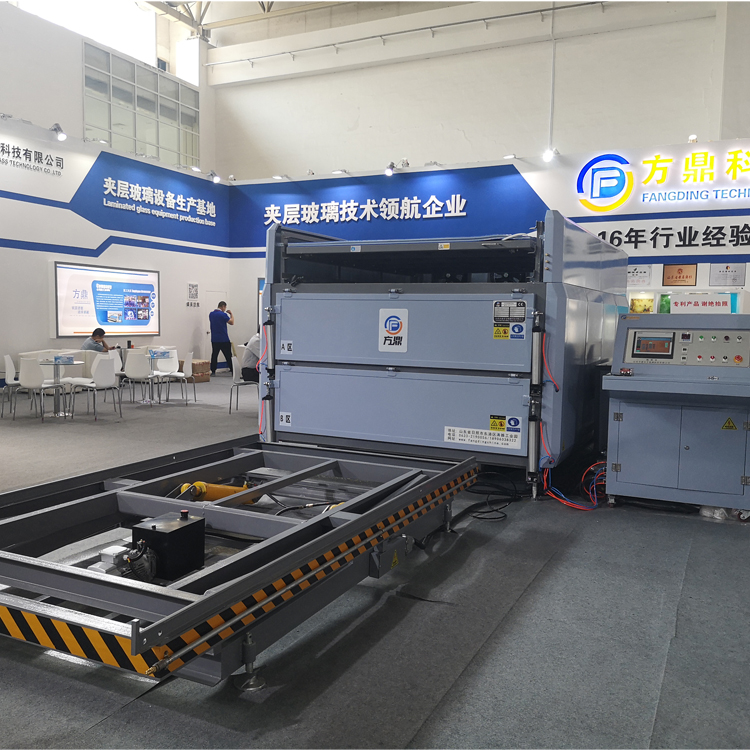

company

The company participated in the world glass industry well-known exhibitions every year, such as Germany Dusseldorf international glass industry exhibition, China international glass industry exhibition, China international window and curtain wall exhibition, Italy Milan international glass industry exhibition, the Middle East (Dubai) international glass exhibition, the United States Atlanta international window and curtain wall exhibition and other exhibitions.

During the exhibition, through the on-site processing of the laminated glass, Fangding presented its unique design style and manufacturing process to the customers!

1. Wrapped with moisture proof film.

2. Wooden case suitable for container loading.

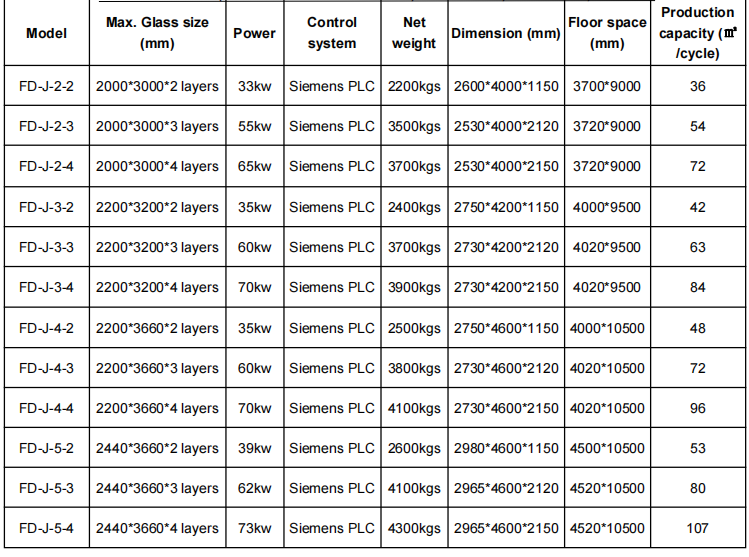

A variety of specifications are available, and custom sizes are also acceptable!

Product detail pictures:

Related Product Guide:

We take customer-friendly, quality-oriented, integrative, innovative as objectives. Truth and honesty is our administration ideal for Manufacturer for Laminated Glass Processing Kiln - EVA Laminated Glass Fabrication Equipment – Fangding, The product will supply to all over the world, such as: Georgia, Liverpool, Bangladesh, We've customers from more than 20 countries and our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Ought to you want anything, don't hesitate to contact us.

We have been looking for a professional and responsible supplier, and now we find it.