OEM Supply Glass Vacuum Laminated Kiln - Tempered Glass Laminating Machine – Fangding

OEM Supply Glass Vacuum Laminated Kiln - Tempered Glass Laminating Machine – Fangding Detail:

Basic Info.

| Silicone Bag Quantity | 3 Sets |

| Trademark | Fangding |

| Origin | China |

| Glass Thickness | 1-36mm |

| Transport Package | Plastic Wrap Film and Plywood |

| HS Code | 847529 |

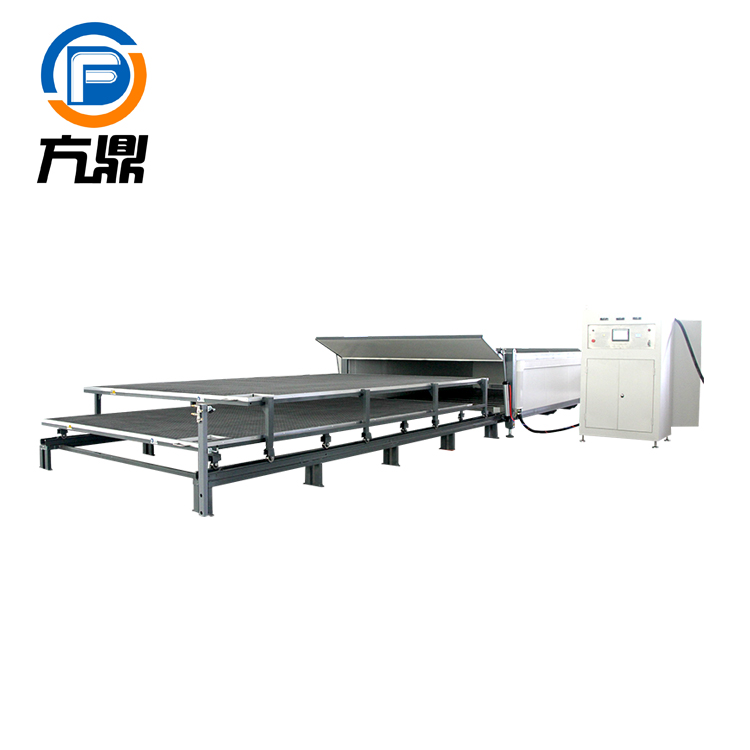

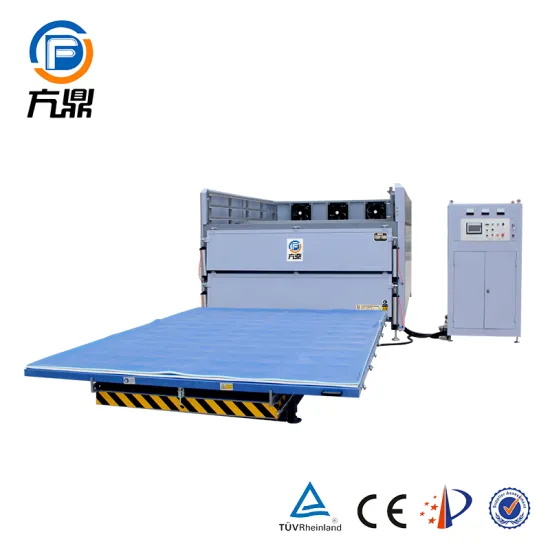

Tempered glass laminating machine FD-J-4-3

Specifications

3 layers glass laminating machine is our popular type. Compared with others ,it is more practical , mid-price ,energy saving .

Features

1. Compared with 2 layers glass laminating machine , 3 layers are equipped with glass lifting table . Large size of glass could be move easily and safe.

2. There has 4 rows of heating tube ,each corner in the furnace could get uniform heat.

3. The bending height for the curved laminated glass could be 200mm.

We could provide the glass laminating machine which processing glass size as small as 1830mm x 2440mm ,as large as 2440 mm x 3660 mm . Or the size could be custom-made.

Technical parameter

| Model | Processing glass size | Rated power | Outside dimension | Production capacity |

| J-2-3 | 2 x 3 x 3 layers |

3500 kgs |

2.53 x 4 x 2.12 m | 54 square meter |

| J-3-3 | 2.2 x 3.2 x 3 layers |

3700kgs |

2.73 x 4.2 x 2.12m | 63 square meter |

| J-4-3 | 2.2 x 3.66 x 3layers |

3800kgs |

2.73 x 4.6 x2.12m | 72 square meter |

| J-5-3 | 2.44×3.66x 3 layers | 4100kgs | 2.95 x 4.6 x 2.12m | 80 square mete |

The accessory

Not only the system but also the spare parts are very important for a good glass laminating machine.

In order to provide a wonderful machine ,we adopts Chinese and international famous brand.

It is convenient for our customer to maintain and change a new one even if it does not work well.

When there has something wrong with the spare parts ,following these steps then you could get a new one :

1. Check the whole machine ,to ensure if there has any other problems

2. Try to fix it according the way on the instruction brochure

3. If it still does not work ,contact us and show the photos or videos

4. If we could not solve the problem by email or telephone ,we would arrange the home service.

Important spare parts list

| Item | Brand |

| Touch screen | Siemens |

| PLC | Siemens |

| Power regulator | TAISEE |

| Air Switch | Schneider |

Samples and applications

Safety glass is a necessary part for a building. And in addition to this ,we want to build a more beautiful one.

Our glass laminating machine could help the glass factory laminating varies kinds of glass.high transparent one ,smart one ,we create more possibility.

Our company

This is our workshop .Our glass laminating machine be produced at here.After 28 steps of process,7 steps of strictly inspection and 3 steps of inspection,we could provide a satisfied machine.

Packaging and Shipping

After so many years ,we sold out so many sets of machine ,our workers are experienced.They know how to load it well and quickly .

The body of the furnace be packed with the wooden case to prevent the damage on the way .

Other parts are covered by plastic wrap.

Before delivery ,we would print a shipping list to confirm that everything would not be forget.

For more details ,please kindly contact with us !

Product detail pictures:

Related Product Guide:

We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for OEM Supply Glass Vacuum Laminated Kiln - Tempered Glass Laminating Machine – Fangding, The product will supply to all over the world, such as: Peru, Naples, UK, We are adhering to the philosophy of attracting customers with the best products and excellent service. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.