-

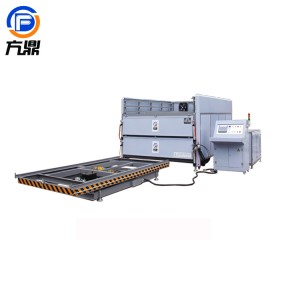

Efficient and Energy-saving Fully Automatic Laminated Glass Production Line

Technical features 1.All parts of the whole line adopt PLC centralized control system,frequency conversion,3 sets of HMI interface operation. 2.The special purpose part is equipped with encoder and servo motor to ensure stability and processing accuracy during production.The whole machine runs smoothly and reliably. 3.The whole production line is designed with high efficiency,energy saving,environmental protection,lower noise and other features. 4.Each part of the whole line can realize comm... -

High-Quality Intelligent Laminated Glass Production Line

Technical features 1.The washing machine has a solid structure,beautiful appearance,energy-saving design,equipped with shutdown protection function,and an independent wind-supply system to make the glass more cleaner. 2.Glass positioning conveyor with fast positioning speed and high precision performance,suitable for the large pieces of glass production. 3.Double-station glass combining machine composed of front and rear stations,which is convenient for glass combination and film cutting,and... -

Easy to Operate Fully Automatic Laminated Glass Production Line

Technical features 1.All parts of the whole line adopt PLC centralized control system,frequency conversion,3 sets of HMI interface operation. 2.The special purpose part is equipped with encoder and servo motor to ensure stability and processing accuracy during production.The whole machine runs smoothly and reliably. 3.The whole production line is designed with high efficiency,energy saving,environmental protection,lower noise and other features. 4.Each part of the whole line can realize comm... -

Advanced Autoclave Capabilities:Enhances Composite Material Manufacturing

The working principle of a autoclave can is to seal carbon fiber composite structural components in a vacuum bag on a mold, place them in the hot press can, and in a vacuum state, go through a process of heating, pressurization, insulation, pressure holding, cooling, and pressure relief to obtain high-performance composite products.

-

Precision SGP Glass Autoclave for Flat and Curved Laminated Glass

It is designed and manufactured in strict accordance with the national standards,It is composed of the body , the heating system, the air circulation system, the heat preservation system, the cooling system and the safety interlock system .The gate is equipped with mechanical and electrical linkage device,it will alarm under over-temperature or over-pressure,and will cool down under over-temperature and relief pressure under over-pressure .

-

Laminated Glass Autoclave — Automotive/Architectural/Ballistic Applications

It is designed and manufactured in strict accordance with the national standards,It is composed of the body , the heating system, the air circulation system, the heat preservation system, the cooling system and the safety interlock system .The gate is equipped with mechanical and electrical linkage device,it will alarm under over-temperature or over-pressure,and will cool down under over-temperature and relief pressure under over-pressure .

-

Precision SGP Glass Autoclave for Flat and Curved Laminated Glass

It is designed and manufactured in strict accordance with the national standards,It is composed of the body , the heating system, the air circulation system, the heat preservation system, the cooling system and the safety interlock system .The gate is equipped with mechanical and electrical linkage device,it will alarm under over-temperature or over-pressure,and will cool down under over-temperature and relief pressure under over-pressure .

-

Precision Composite Autoclaves

The working principle of a autoclave can is to seal carbon fiber composite structural components in a vacuum bag on a mold, place them in the hot press can, and in a vacuum state, go through a process of heating, pressurization, insulation, pressure holding, cooling, and pressure relief to obtain high-performance composite products.

-

Factory Sale EVA Glass Laminating Oven with CSA Certificate

Type: Glass Laminating Machine

Certification: CE, ISO, FDA, UL, UR, PCI, PDA

Control System: PLC

Condition: New

Name: Factory Sale EVA Glass Laminating Oven with CSA Ce

Model: Fd-J-4-4

-

Four Layers Glass Laminated Machine with EVA Film

Type: Glass Laminating Machine

Certification: CE, ISO, FDA, UL, UR, PCI, PDA

Control System: PLC

Condition: New

Name: Four Layers Glass Laminated Machine with EVA Film

Model: Fd-J-5-4

-

PVB Film

Product Parameters Physical property SIUnits value Test Standards Tensile strength ≥42Mpa GB/T528-2009 tear resistance ≥ 40 kN/m GB/T529-2008 Binding force with inorganic glass ≥22 kN/m GJB446-1988 hardness 80 ~85IRHD GB/T531.1-2008 Glass transition temperature (Tg) ≤-68℃ GB/T19466.2-2004 Glass Transition Temperature ≤-60℃ GB/T 43128-2023 Transmission ≥90% GB/T37831-2019 fog ≤0,3% GB/T37831-2019 Product Features Company presentation Fangding Technology Co., Ltd. is a hi... -

TPUGL560 Intermediate Film For Laminating Glass

TPU intermediate film is a thermoplastic polyurethane elastomer material.Optical grade TPU is known as the pearl on the crown. It has excellent optical performance, aging resistance, good adhesion performance, and low temperature non brittleness. It is a key material essential for high-speed trains, helicopters, passenger planes, transport plane windshields, bulletproof glass armor, and ship windshields.