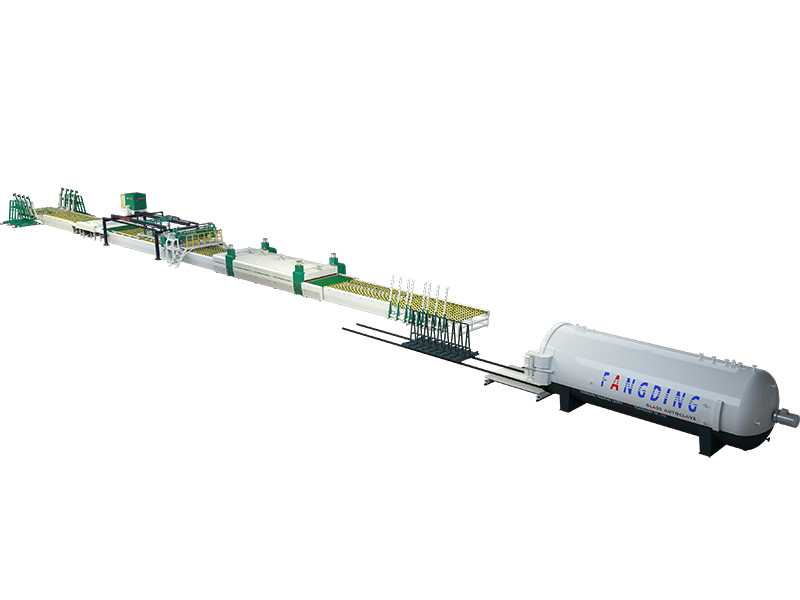

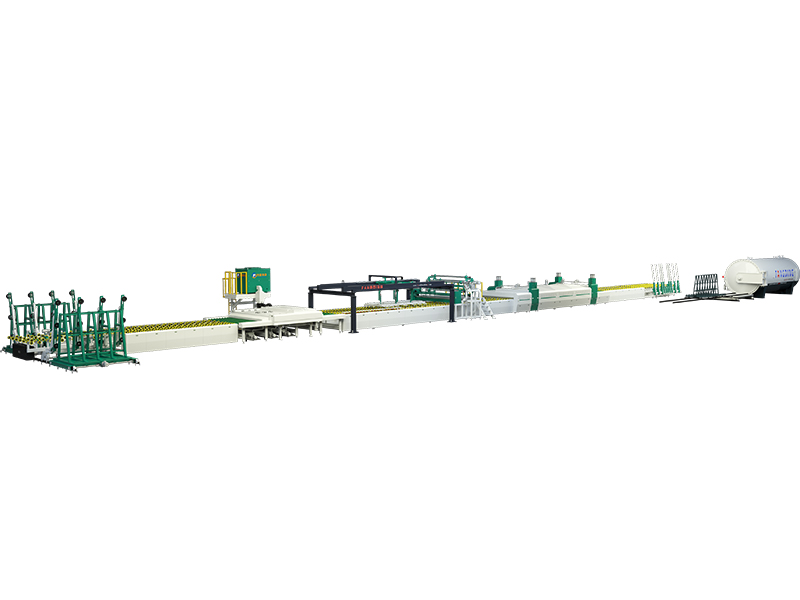

Professional Design Double System Glass Laminated Machine - Glass laminating line – Fangding

Professional Design Double System Glass Laminated Machine - Glass laminating line – Fangding Detail:

The automatic glass laminating line is composed by 11 parts, which are the Automatic mechanical loading machine, the Transition conveyor for loaded glass, the Smart glass cleaning & drying machine, the Automatic glass positioning machine, the Automatic movable suction hanger, the Six roller PVB film rack, the Transition conveyor for assembled glasses, the Forced convection infrared pre-presser, the Transition conveyor for unloaded glass, unloading machine for large size glasses,and the Forced convection autoclave. To meet the different requirements of our customers from domestic and abroad, we can provide a full set of automatic production line and a semi-automatic production line both.

1. All sections of the line adopt PLC centralized control systerm, frequency control and three HMI interface operations.

2. The special purpose segment is equipped with encoder and servo motor to ensure equipment stability and machining accuracy.

3. High efficiency, energy saving, environmental protection, noise and other special controls shall be considered in the whole line design.

4. The film spreading machine adopts automatic film placing and electric film returning.6 rolls of plastic film lay, easy to operate, easy to replace plastic film.

5. the structure of the initial press is reasonable, easy to operate.The whole machine runs smoothly and reliably, and is centrally controlled by the chip room.The heating area is evenly distributed, and domestic medium-wave infrared heating tube is adopted for heating. The temperature is measured and controlled in the zone, and the maximum temperature is 250℃(adjustable).

6. adopt mechanical turnover unloading table to unload.

7. The glass autoclave is automatically controlled by PLC and operated by man-machine interface to achieve safety, reliability, high efficiency and energy saving.

8. Except for the monitoring of the operator at the loading and unloading stations, the operation of other lines is fully automatic, realizing intelligent production, reducing personnel risks and production costs.

Product detail pictures:

Related Product Guide:

The corporate keeps towards the operation concept scientific administration, superior quality and performance primacy, client supreme for Professional Design Double System Glass Laminated Machine - Glass laminating line – Fangding, The product will supply to all over the world, such as: Haiti, Singapore, South Korea, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we have a pleasant and long terms business together!!!

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!