Fangding hot sale laminated glass making oven

Basic Info.

| Model | Two layers |

| Condition | New |

| Max Processing Glass Size | 2000X3000/2200x3200/2200x3660/2440x3660mm |

| Max Glass Thickness in Each Silicone Bag | 40mm |

| Forming Cycle | 70-120 Min/Cycle |

| Production Capacity in 8 Hours | Depends |

| Working Temperature | 90-150 degrees |

| Floor Space | 3700*9000/4000x9500mm/4000x10500/4500x10500mm |

| Container Suitable | 20OT/40HQ |

| Trademark | Fangding |

| HS Code | 8475291900 |

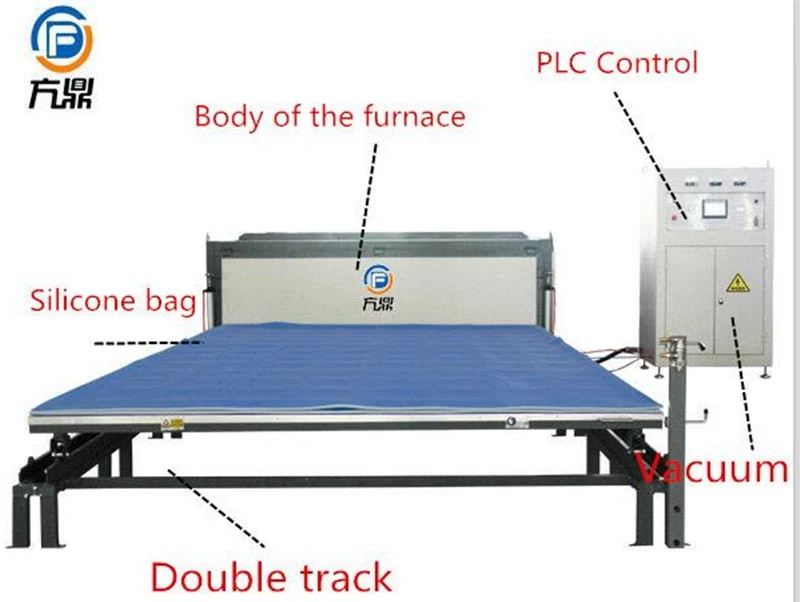

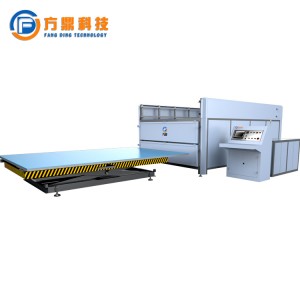

2 trays EVA glass laminating machine

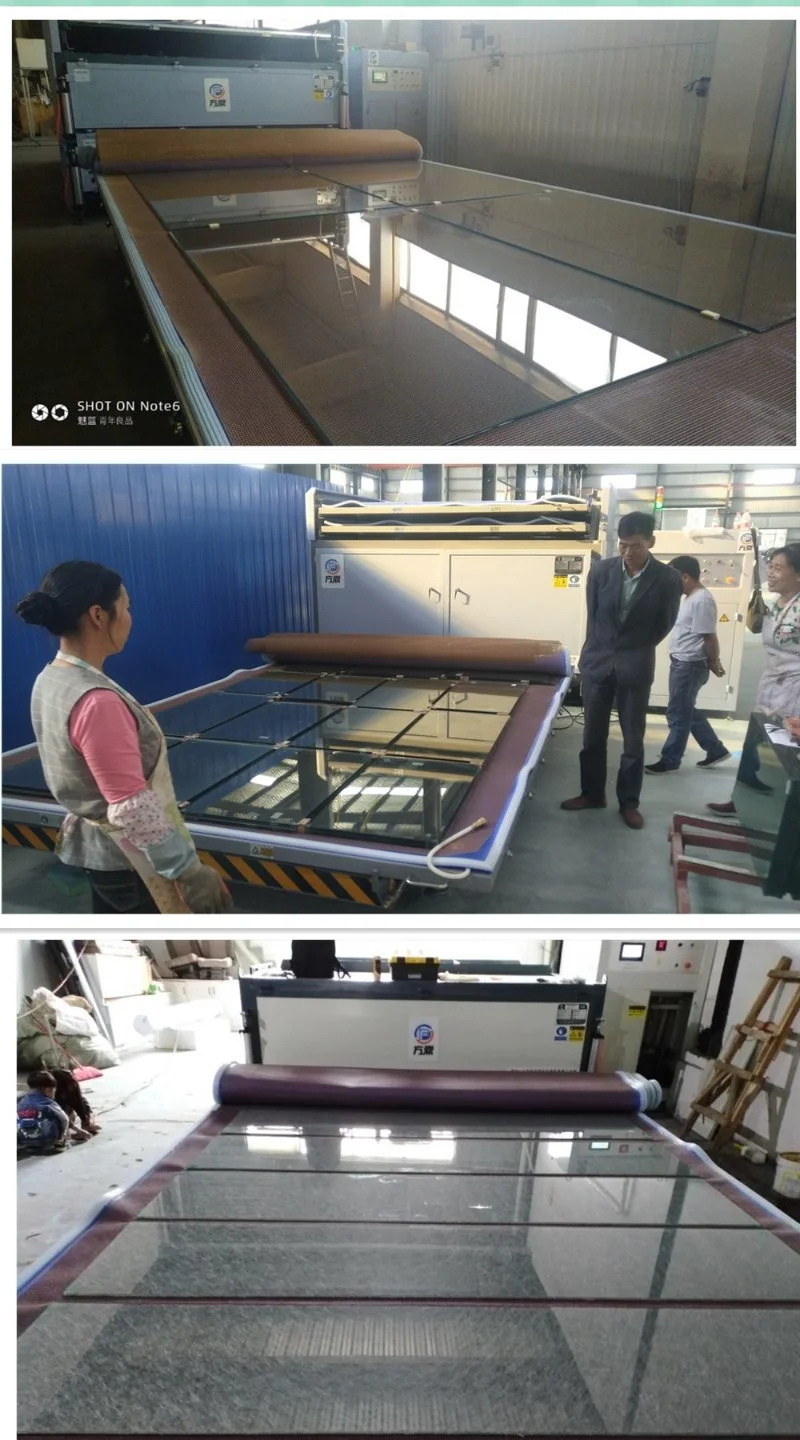

We sold more than 200 sets EVA glass laminating machine every year in domestic and abroad, have good reputation. Below is one of our star products.

The working principle of our EVA laminated glass machine is vacuum and heating. After put the glass in the vacuum bag, the vacuum system will vacuumize the air from the bag, create a vacuum environment. This process ensure no bubbles appear between the glasses. The heating system will melt the film so that the two pieces of glasses can be firmly stick together.

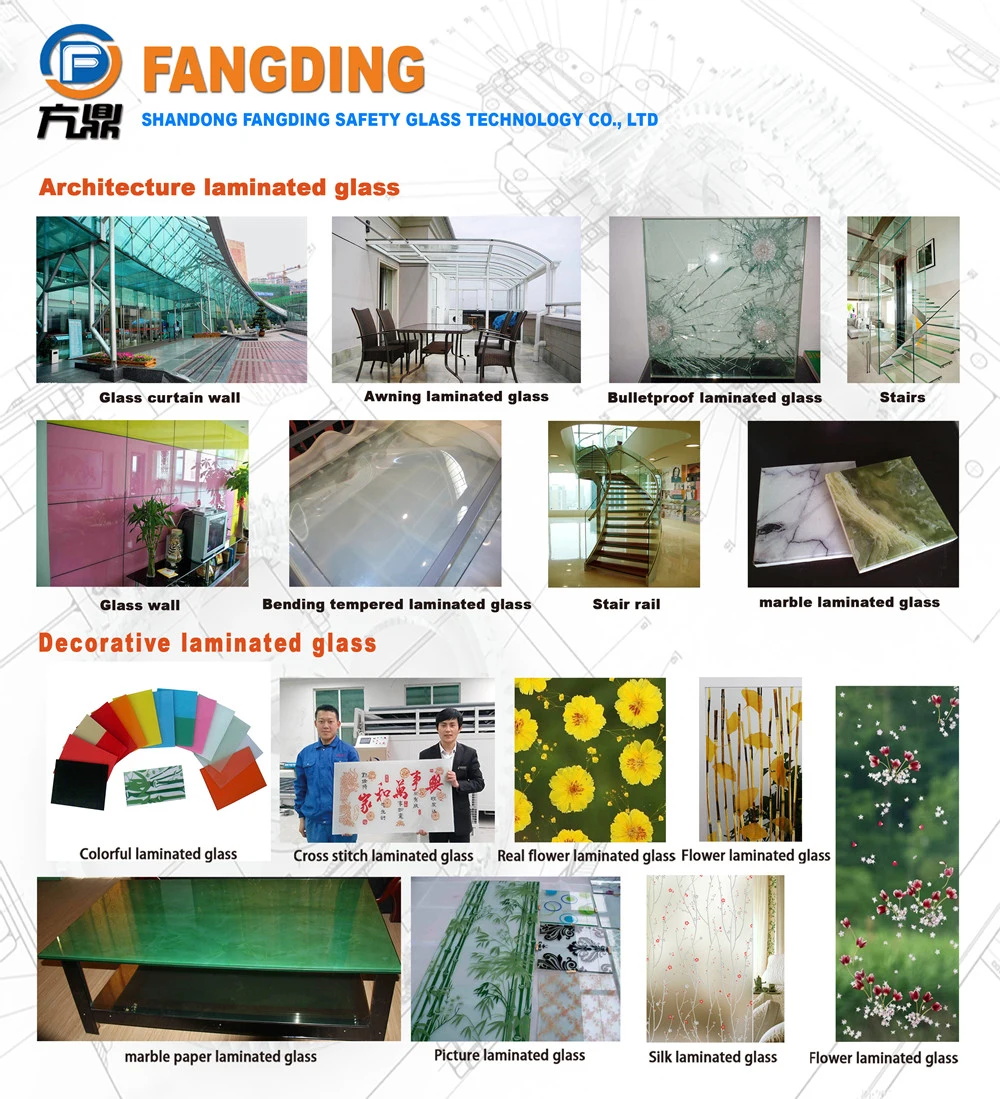

Application of this laminated glass machine

Fangding laminating machine is designed to produce Architecture laminated glass used for outdoor building.

This building laminated glass requested high technology on machine than decorative glass.

We ensure the finished laminated glass with excellent performance:

Without any bubbles, much transparency, clean at the edges.....

The machine applications:

1. Architecture laminated glass (float / tempered/ curved tempered laminated glass, etc)

2. Top grade decorative laminated glass(Such as marble paper, silk, dry flower, acrylic, floor tile laminated glass etc)

3. PDLC/LED laminated glass, solar panel laminated glass.

Main features

* Process EVA/TPU/SGP laminated glass

* Product yield at least 99%

* Energy saving and small space

* Adopt advanced heating technology

* Only 0.5kw for 1 sqm of laminated glass

* Labor saving, 2 workers are enough.

* Selling to more than 60 countries®ions

* No clients' complaint in recent 6 years

Technican data

The machine size is customized, 1830x2440mm, 2000x3000mm, 2200x3200mm, 2200x3660mm, 2440x3660mm, 2200x4000mm, 2500x4500mm, 2500x5000mm,2800x6000mm are all hot sales size.

There are basiclly 3 models for choice according different machine sizes.

4 layers, 3 layers, 2 layers.

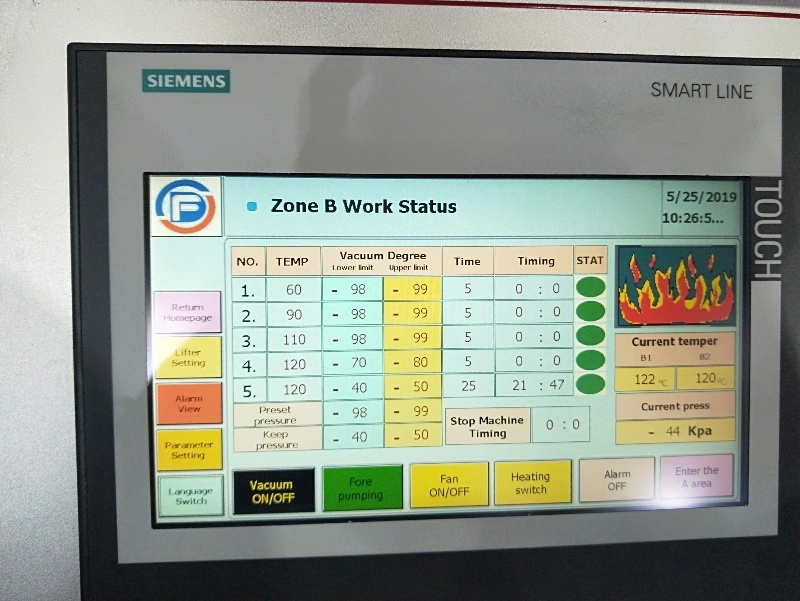

Advanced PLC control system.

Touch Screen Panel all program completed automatically.

Heating time and temperature adjusted according to the glass thickness.

Working status shown on touch screen.

Heating system

The distribution of Stainless Steel heating tube like carpet

The temperature difference inside the furnace do not exceed 5 degree

All positions of the glass are heated evenly and fast.

Advanced system

The machine use wind-cooling vacuum pump, Germany design

Continuously work for 24 hours. Vacuum rate reach up to -0.09 - -0.098Mpa.

It's equipped with vacuum buffer tank in case interruption of electricity supply,It can keep the vacuum rate for 1 day.

The maintenance reminder on touch screen, automaticlly.

Our silicone bag thickness is 3 mm, it's a tear resistant material, and could stand high temperature to 180°C.

Automatic lifting table

Add remote control and Omron limit switch, work like elevator, more safety and convenient.

We are designer of this EVA glass laminating machine, have 6 patent on this machine.

Pay more attention to the machine quality and details of design.

Our workshop

Fangding relevant product

We have 5 big production line for:

* EVA glass laminating machine,

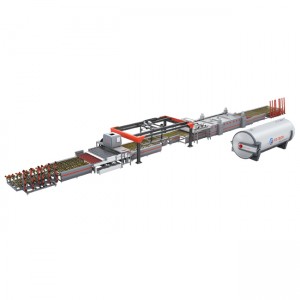

* PVB laminating line included autoclave,

* EVA film,

* TPU film

* Heat soak test furnace.

As the first enterprise to produce EVA glass laminating furnace in China, we have gained much experience in laminated glass field, can provide the whole solution for kinds laminated glass.

Fangding company introduction:

Fangding Technology Co., Ltd located in Rizhao, Shandong province. China.

The company is a national high-tech enterprise with R&D, production, sales and service department since 2003.

The company covers an area of 20000 sqm, the registered capital is 100 million yua.

Own the pressure vessel production qualification, has several modern production workshops.

We have got the CE certificate ISO9001:2008 quality management system certificate, CE certification, Canada CSA certification, have sold many sets to abroad, customers are much satified with our machine.

More information, freely contact me any time!