-

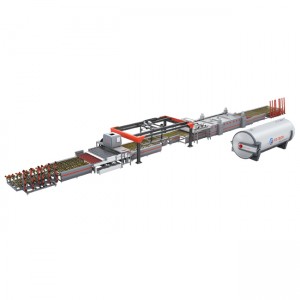

Automatic laminated glass production line with autoclave

We have experienced R&D team, which can meet customers’ requirements of various sizes and output. Have pressure vessel production qualification.

-

Dependable Autoclaves for Premium Composites

The working principle of a autoclave can is to seal carbon fiber composite structural components in a vacuum bag on a mold, place them in the hot press can, and in a vacuum state, go through a process of heating, pressurization, insulation, pressure holding, cooling, and pressure relief to obtain high-performance composite products.

-

FOUR LAYER LAMINATED GLASS MACHINE

The machine have 2 operation systems,can laminate different kinds of glass with different parameters at the same time,realize cycle work,reduce costs and increase efficiency.

The independent vacuum system has the functions of power failure and pressure maintenance,oil-water separation,pressure relief alarm,maintenance reminder,dust prevention and noise reduction,etc.

Multi-layer independent heating and modular area heating control,make the machine has fast heating speed,high efficiency and small temperature difference.

The insulation layer is seamlessly processed to reduce heat loss,the insulation effect is stronger,and it is more energy-saving.

The machine adopts PLC control system and the new humanized UI interface,the whole process of machine status can be visualized,and all procedures can be completed automatically.

New upgraded design,the lifting platform has a one-button lifting function,and the full-load glass lifts without deformation and rebound. -

DOUBLE LAYER LAMINATED GLASS MACHINE

Adopt the unqiue design structure of double track,which can be used flexibly by single or double stations.

Super large curved architecture laminated glass can be formed at one time.

The machine is heating fast and evenly,energy saving 40%~50%.

The machine has the function of reservation startup,timed shutdown,automatic door opening and cloud control. -

High clear color EVA film for laminated glass

EVA film manufacturer with 20 years experience. Super clear, high clear, color and special film are all available.

-

Tempered Glass Laminating Machine

Type: Glass Laminating Machine

Certification: CE, ISO, UL, CSA

Control System: PLC

Condition: New

Layer: 3

Processing Glass Size: 2.2 X 3.66

-

Glass laminated autoclave with automatic production line

We provide fully automatic laminated glass production line and autoclave, and design a reasonable scheme for you according to your needs.

-

PVB complete glass laminated line solution

Our factory covers an area of more than 20,000 square meters and independently produces laminated glass production lines, especially autoclaves. We are one of the few domestic manufacturers with the qualification for producing pressure vessels.

-

SSP-Series-Double-Chambers-Glass-Tempering-Furnace-2-300x300.jpg)

Forced convection glass tempering furnace

Horizontal Rollers Hearth Double Chambers (Forced Convection) Flat Glass Tempering Furnace is mainly used to produce architecture glass, advanced domestic appliances, decoration glass , Automobile&Train&Ship glass, high quality thin tempered and laminated glass, lighting glass.

-

PVB automatic glass laminating line

Automatic PVB laminated glass production line. Glass Loading → Transition → Cleaning and drying→Glass combination → Transition → Preheat and prepress → Unloading → Enter autoclave → Finished product

-

TPU Intermediate Film For Laminating Glass

TPU intermediate film is a thermoplastic polyurethane elastomer material.Optical grade TPU is known as the pearl on the crown. It has excellent optical performance, aging resistance, good adhesion performance, and low temperature non brittleness. It is a key material essential for high-speed trains, helicopters, passenger planes, transport plane windshields, bulletproof glass armor, and ship windshields.

-

Full Automatic Laminated Glass Production Line

Technical features 1.All parts of the whole line adopt PLC centralized control system,frequency conversion,3 sets of HMI interface operation. 2.The special purpose part is equipped with encoder and servo motor to ensure stability and processing accuracy during production.The whole machine runs smoothly and reliably. 3.The whole production line is designed with high efficiency,energy saving,environmental protection,lower noise and other features. 4.Each part of the whole line can realize comm...