Ce Standard Switchable Glass Laminating Machine with Pdlc Magic Film

Fangding Technology Co.,Ltd.

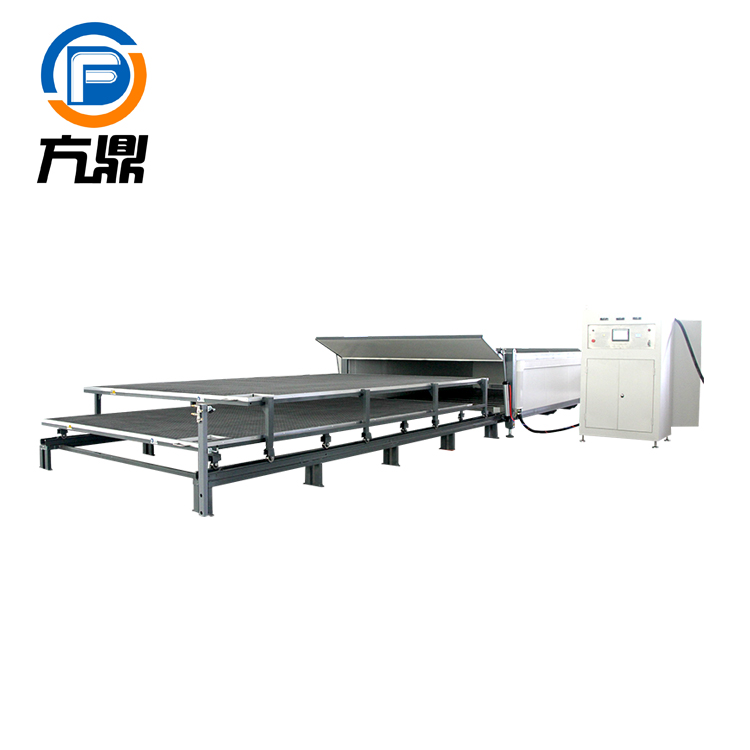

FOUR-LAYER,DOUBLE CIRCULATION

EVALAMINATED GLASS MACHINE

Newly Upgraded Safe and Reassuring

Product Introduction

| Model NO. | FD-J-2-2 |

| Condition | New |

| Max Processing Glass Size | 2000X3000mm |

| Max Glass Thickness in Each Silicone Bag | 40mm |

| Forming Cycle | 75-120 Min/Cycle |

| Production Capacity in 8 Hours | 115sqm (If 80% Full Furnace Loaded) |

| Working Temperature | 90-150c |

| Floor Space | 3700*9000 |

| Container Suitable | One 20" Open Top Container |

| Trademark | Fangding |

| Specification | 2000x3000x2 layers |

| HS Code | 8475291900 |

| Grinding Head Number | 20 |

| Electric Power | 3-Phase AC 220-440V)/40kw |

| Min Processing Glass Size | 100X100mm |

| Max Bending Deep | 370mm or Customized |

| Max Production Capacity in One Cycle | 36m |

| Operation Platform | 2 Layers |

| Max Part Exterior Dimension | 4000*2550*1100mm |

| Net Weight | 2200kg |

| After-Sale Service | Home Installation and Technical Training |

| Transport Package | Wooden Box |

| Origin | China |

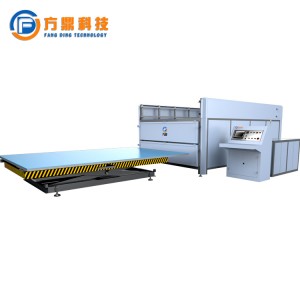

Scientific Design

Selling point description

FEATURES

Fangding laminating machine is designed to produce Architecture laminated glass used for outdoor building.

This building laminated glass requested high technology on machine than decorative glass.

We ensure the finished laminated glass with excellent performance:

Without any bubbles, much transparency, clean at the edges.....

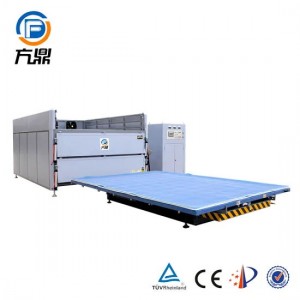

The machine applications:

1. Architecture laminated glass (float / tempered/ curved tempered laminated glass, etc)

2. Top grade decorative laminated glass(Such as marble paper, silk, dry flower, acrylic, floor tile laminated glass etc)

3. Bulletproof laminated glass

4. PDLC/LED laminated glass, solar panel laminated glass.

5. Windshield

* Process EVA/TPU/SGP laminated glass

* Product yield at least 99%

* Double independent systems

* Energy saving and small space

* Adopt advanced heating technology

* Only 0.5kw for 1 sqm of laminated glass

* Labor saving, 2 workers are enough.

* Selling to more than 60 countries®ions

* No clients' complaint in recent 6 years

CUSTOMER CASE

The equipment is sold to Asia, Europe, Ameriaca, Southeast Asia, and has received unanimous praise from customers;

Good customer performance and the ability to mass produce orders;

Morecustomers choose to order a second unit and repeat orders for high-pressure reactors, production lines, and other products.

CUSTOMER USE CASES

The products produced by customers using equipment can be seen everywhere in daily life, such as wire clips, colored decorative glass, etc; And it has also been used in important engineering cases of world-renowned buildings and scenic spots such as glass bridges and lighthouses.

CERTIFICATE OF HONOR

R&D TECHNOLOGY TEAM

Hold a technical

review meeting

before production

Calculation based

on drawings

before production

Multiple

experienced

technical engineers

EXHIBITION STYLE

CONTACT US

Jennifer Zhu

HOT LINE +86-18906338322

Website: https://en.fangdingchina.com/

Email: sales2@foundite.com

Add: Huifeng Road, Taoluo Industrial Park, Donddang District, Rizhao City, Shandong Province, China