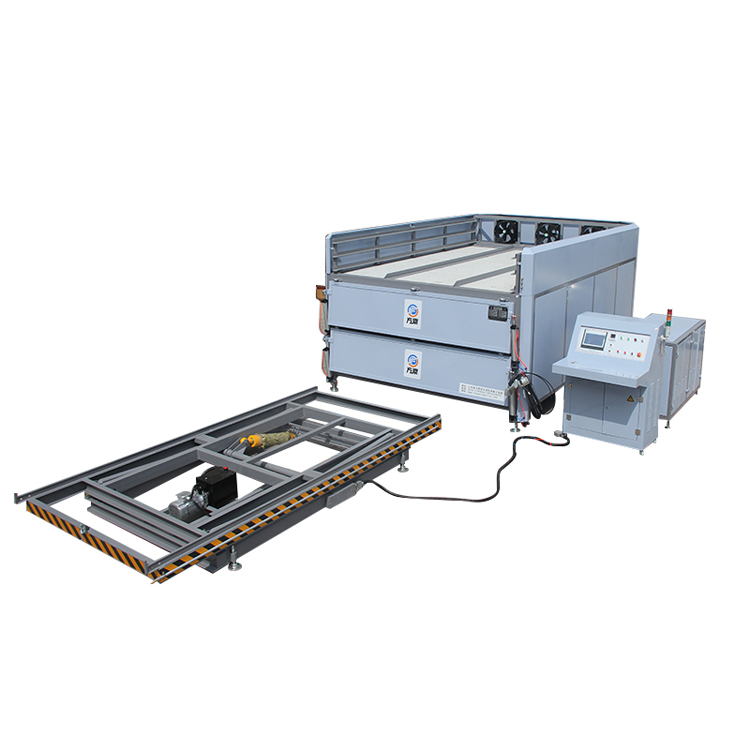

Four layers glass lamination machine with dual independent system

Fangding Technology Co.,Ltd.

FOUR-LAYER,DOUBLE CIRCULATION

EVALAMINATED GLASS MACHINE

Newly Upgraded Safe and Reassuring

Product Introduction

| Model | Max.Glass size(mm) | Power | Control system | Net weight | Dimension(mm) | Floor space(mm) | Production capacity(m²/cycle) |

| FD-J-2-2 | 2000*3000*2 layers | 33kw | Siemens PLC | 2200kgs | 2600*4000*1150 | 3700*9000 | 36 |

| FD-J-2-3 | 2000*3000*3 layers | 55kw | Siemens PLC | 3500kgs | 2530*4000*2150 | 3720*9000 | 54 |

| FD-J-2-4 | 2000*3000*4 layers | 65kw | Siemens PLC | 3700kgs | 2530*4000*2150 | 3720*9000 | 72 |

| FD-J-3-2 | 2200*3200*2 layers | 35kw | Siemens PLC | 2400kgs | 2750*4200*1150 | 4000*9500 | 42 |

| FD-J-3-3 | 2200*3200*3 layers | 60kw | Siemens PLC | 3700kgs | 2730*4200*2120 | 4020*9500 | 63 |

| FD-J-3-4 | 2200*3200*4 layers | 70kw | Siemens PLC | 3900kgs | 2730*4200*2150 | 4020*9500 | 84 |

| FD-J-4-2 | 2200*3660*2 layers | 35kw | Siemens PLC | 2500kgs | 2750*4600*1150 | 4000*10500 | 48 |

| FD-J-4-3 | 2200*3660*3 layers | 60kw | Siemens PLC | 3800kgs | 2730*4600*2120 | 4020*10500 | 72 |

| FD-J-4-4 | 2200*3660*4 layers | 70kw | Siemens PLC | 4100kgs | 2730*4600*2150 | 4020*10500 | 96 |

| FD-J-5-2 | 2440*3660*2 layers | 39kw | Siemens PLC | 2600kgs | 2980*4600*1150 | 4500*10500 | 53 |

| FD-J-5-3 | 2440*3660*3 layers | 62kw | Siemens PLC | 4100kgs | 2965*4600*2120 | 4520*10500 | 80 |

| FD-J-5-4 | 2440*3660*4 layers | 73kw | Siemens PLC | 4300kgs | 2965*4600*2150 | 4520*10500 | 107 |

Scientific Design

Selling point description

The latest Fangding 4-layer laminated glass machine introduction

4 layers machine equipped with double independent system. Mainly working system includes heating, vacuum, PLC control, glass lifting table,cooling.

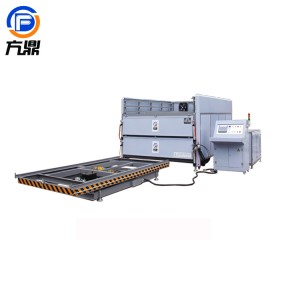

The PLC control cabinet adopts piano type design, easy to operate, beautiful appearance and it will be more convenient to write down or place something.

The vacuum pumps and electrical elements are separated, so that could reduce the damage to the electrical elements caused by the vibration of the vacuum pump; improve the service life of those spare parts.

FEATURES

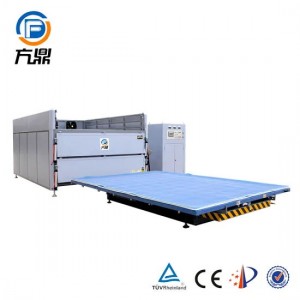

1. The machine have 2 operation systems, can laminate different kinds of glass with different parameters at the same time, realize cycle work, reduce costs and and increase efficiency.

2. The independent vacuum system has the functions of power failure and pressure maintenance, oil-water separation, pressure relief alarm, maintenance reminder, dust prevention and noise reduction, etc.

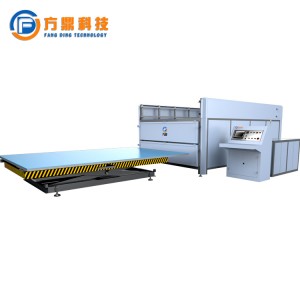

3. Multi-layer independent heating and modular area heating control, make the machine has fast heating speed, high efficiency and small temperature difference.

4. The insulation layer is seamlessly processed to reduce heat loss, the insulation effect is stronger, and it is more energy-saving.

5. The machine adopts PLC control system and the new humanized UI interface, the whole process of machine status can be visualized, and all procedures can be completed automatically.

6. New upgraded design, the lifting platform has a one-button lifting function, and the full-load glass lifts without deformation and rebound.

CUSTOMER CASE

The equipment is sold to Asia, Europe, Ameriaca, Southeast Asia, and has received unanimous praise from customers;

Good customer performance and the ability to mass produce orders;

Morecustomers choose to order a second unit and repeat orders for high-pressure reactors, production lines, and other products.

CUSTOMER USE CASES

The products produced by customers using equipment can be seen everywhere in daily life, such as wire clips, colored decorative glass, etc; And it has also been used in important engineering cases of world-renowned buildings and scenic spots such as glass bridges and lighthouses.

CERTIFICATE OF HONOR

R&D TECHNOLOGY TEAM

Hold a technical

review meeting

before production

Calculation based

on drawings

before production

Multiple

experienced

technical engineers

EXHIBITION STYLE

CONTACT US

Jennifer Zhu

HOT LINE +86-18906338322

Website: https://en.fangdingchina.com/

Email: sales2@foundite.com

Add: Huifeng Road, Taoluo Industrial Park, Donddang District, Rizhao City, Shandong Province, China